Green Product Management

Unimicron is committed to the implementation of green product management with the three principles of “compliance with green specifications and requirements”, “green procurement”, and “green supply chain”, and sets the quality target of HSF. The use of environmentally hazardous substances on products is strictly prohibited, which considers green materials in the process design. The purchased raw materials comply with the requirements of international laws and regulations such as the Restriction of Hazardous Substances Directive (RoHS), Registration, Evaluation, Authorization, and Restriction of Chemical (REACH), Directive of Packaging and Packaging Waste, China RoHS, California Proposition 65, Montreal Convention, etc. 100% products comply with the requirements of RoHS and REACH. The principles of green products and continuous improvement are implemented, to satisfy customers and comply with the requirements for green materials by international environmental protection regulations and fulfill the social responsibility of environmental protection.

| Topics |

Chemical Safety |

| Policy |

|

| Commitment |

- Green products that 100% comply with international regulations, industry standards and customers’ requirements

|

| Division |

|

| Resources Invested |

- Establish QC 080000 Hazardous Substance Management System

- Establish a testing report management system

- Establish an announcement and return system of suppliers’ hazardous substance declaration documents

- Set up XRF analyzer to test hazardous substance

|

| Grievance Mechanism |

- Customer Service System, Whistleblower hotline and mailbox

|

| 2022 Targets |

- Customer satisfaction rate with HSF quality: 4.48 (out of 5)

- Achievement rate of immediate legal updates: 100%

- XRF testing pass rate of incoming materials and finished products: 100%

- Supplier’s HSF quality audit pass rate: 100%

|

| Actions |

- Source management

- Process management

- Customer relationship management

|

| 2022 Achievements |

- Customer satisfaction rate with HSF quality: 4.8 (out of 5)

- Achievement rate of immediate legal updates: 100%

- XRF testing pass rate of incoming materials and finished products: 100%

- Supplier’s HSF quality audit pass rate: 100%

|

Green Material Committee

Unimicron is the second largest professional PCB and carrier board manufacturer in the world in terms of revenue. In order to comply with customer requirements and international laws and regulations, we have established a Green Material Committee in the Printed Circuit Board and Carrier Board Division, which integrates the departments of quality management, materials, products, R&D, manufacturing, and business. Green materials are taken into consideration in the process design, and harmful substances are fully controlled in four major processes, including quality planning, supply chain and material flow, manufacturing, and quality assurance. Internal operations are carried out, and the status and requirements the Company's green products is continuously confirmed through the QC080000 management system. In the event of changes or amendments to customers’ specifications or international regulations, we will conduct internal evaluations, adjust control standards and operating modes, and notify the relevant units by way of announcements to ensure that products meet customer requirements and comply with relevant laws and regulations and green product regulations, to meet quality requirements and customer satisfaction.

HSF Quality Policy

To implement the four major principles of HSF quality policy, Unimicron has established various indicators to regularly track performance and achievement rates, to ensure that the policies are implemented and meet customer needs. From 2013 to 2022, the achievement rate of all HSF quality indicators was 100%, and there were no returns from customers due to HSF non-compliance.

Satisfaction of Customer

Obey Prescription

Green Products

Continue Improvement

Establish HSF Management System

2005

Restricted RoHS 6 Substances

2007

Monitoring Incoming and Outgoing Hazardous Substances with Tube-Based Portable XRF

2008

IECQ QC080000 Certification

Green Partner Certification from Customers (2008~2010)

2010

Green Activity Certification

Green Partner Certification (2010~2012)

REACH SVHC by Following Laws from 2010

2011

Incoming and Outgoing Hazardous Substances with a Desktop X-ray Fluorescence Spectrometer (XRF)

Eco-Partner Certification

2012

Obtained Green Partner Certification (2012~2014)

2014

Manage RoHS 4 Specific Phthalates

2016

use of RoHS 4 Specific Phthalates

Green Partner Certification (2016~2018)

2018

Obtain Green Partner Certification (2018~2020)

2019

Obtain IECQ QC080000:2017 Certification

2021

Obtain Green Partner Certification (2021~2023)

HSF Quality Indicators and Performance

| Indicator |

2022 Targets |

2022 Achievements |

2023 Targets |

| Number of Returned Goods Due to Conformity With HSF (Cases) |

0 |

100 |

0 |

| Real-Time Update Completion Rate of International/Customer Regulations on Hazardous Substances (%) |

100 |

100 |

100 |

| The Pass Rate of Hazardous Substance Inspection Conducted Internally From Incoming to Shipping and by a Commissioned Third-Party Certification Body (%) |

100 |

100 |

100 |

| Deficiency Improvement Rate of Regular and Irregular HSF Internal/External Audit (%) |

100 |

100 |

100 |

| Completion Rate of HSF Regular Training (%) |

100 |

100 |

100 |

Hazardous Substances Management

All raw materials, packaging materials and chemicals required in the manufacturing process of products are incorporated into the management system to achieve comprehensive management. In order to fulfill our responsibility and contribution as a global citizen, we are committed to not using banned environmental management substances, while complying with the current laws and regulations, meeting the needs of our customers, and protecting the global environment to reduce the impact on the ecosystem. We established measures for source, process, and finished product management to comply with international standards and customer requirements for controlled substances, and to curb the environmental and social hazards caused by the life cycle of our products.

| # |

Mechanism |

Implementation Measures |

2022 Results |

| 1 |

Source Management |

- Establish and regularly update the Hazardous Substance List.

- Register and evaluate the use of raw materials, and conduct chemical audits during the procurement.

- The supplier shall provide us with a third-party inspection report, which shall be updated annually.

- Only use materials that have been approved by the Green Material Committee.

|

- Approximately 1,140 items are on the raw material management list

- New raw materials are 100% reviewed

- The compliance rate of RoHS testing is 100%

- Suppliers’ third-party testing reports a pass rate of 100%.

- 100% green material procurement rate (in compliance with RoHS)

|

| 2 |

Process Management |

- Test incoming materials and products for Hazardous substances by XRF analyzer.

- "Halogen-free" and "lead-free" are used for the entire production process unless specified by the customer.

- Identify and manage customers' specified materials from incoming materials, receiving materials, and manufacturing to warehousing of finished products.

|

- 4,099 incoming materials passed by XRF testing, 100% passed

|

| 3 |

Product Testing |

- Test incoming materials and products for Hazardous substances by XRF analyzer.

- Samples of products tested for RoHS, Hazardous Substances, etc. by third party.

- Regularly survey customer satisfaction with HSF quality for continuous improvement.

|

- 100% passed by third-party inspection

- 4,329 finished products passed by XRF testing, 100% passed

- Customer HSF quality satisfaction of 4.8 is higher than the target of 4.48 (out of 5)

|

1.Source Management

To implement the source management of green products, Unimicron has developed a complete internal control process and operation regulations for hazardous substances, established a raw material audit mechanism, adopted the E-Pr system for management, and required suppliers to provide third-party testing reports and updates annually. We published the green procurement requirements and conflict minerals investigation form. Also, request suppliers to confirm/reply with a non-use (banned and restricted substances) guarantee letter and conflict-free minerals. Materials are required to comply with EU regulations such as RoHS, REACH, halogen-free, conflict-free minerals, etc., and listed in the Qualified Materials List after passing Unimicron's internal audit. If there are specific requirements by the customer, we will comply with the customer's control standards and supplier management regulations to fulfill our commitment to "100% compliance with international regulations, industry standards and customer requirements for green products".

Review Process

New Materials

UMT Prohibited

Substances Assessment

Banned

Procurement and Use after Permission

Risk Management

Control Measure

Hazardous Substance List and Reduction Plan:Based on RoHS, REACH Substances of Very High Concern (SVHC), IEC 62474, customer regulations and other international regulations, we develop a Hazardous Substance Control List and related reduction plan to control the use of substances in the list. When necessary, through the monitoring of the list of hazardous substances and the reduction plan, implement reduction or declaration according to customer needs.

REACH Compliance Declaration: Investigate the compliance of suppliers with REACH and implement source management of raw materials.

Restriction of Hazardous Substances Operational Procedures:To regulate the Standard Operating Procedures of division in handling hazardous substances.

Raw Material Survey

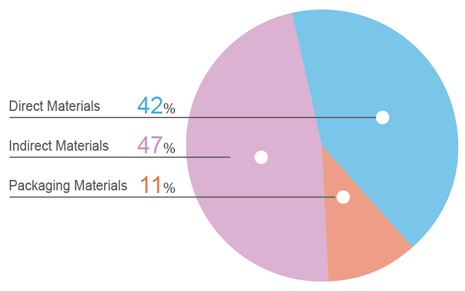

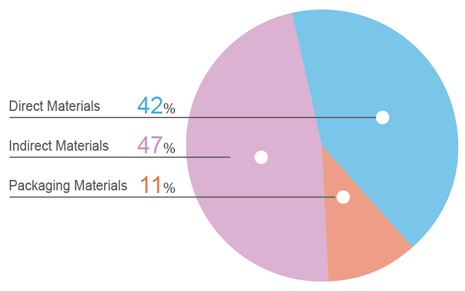

“100% Green Products in accordance with International Regulations, Industry Standards, and Customer Requirements” is Unimicron's commitment to green products. In order to comply with the requirements of the RoHS and REACH, Unimicron carried source and finished product management according to the specifications of the management systems and requested suppliers to survey hazardous substances to ensure that the raw materials were complied with the hazardous substances by RoHS and REACH. In 2022, there were 1,358 RoHS reports from Taiwan facilities for managing and reviewing suppliers, including 574 for direct materials, 638 for indirect materials, and 146 for packaging materials, which were 100% completed.

Hazardous Substance Control

In order to promote green product management and product safety, Unimicron's products are currently banned to use environmentally hazardous substances, and in accordance with EU regulations (e.g. RoHS, REACH, IEC 62474, etc.), a total of 1,140 substances are listed in 11 regulatory directives and customer-specific requirements, including GADSL (274 substances) and Prop65 (970 substances), which are mainly published on the official website of the regulations.

Unimicron’s products are one of the components of complex electronic products, and the most important concern for customers is the EU REACH SVHC and RoHS hazardous substances restriction directive. Unimicron’s products give priority to green materials that comply with regulations and customer requirements. Except for customer-specified materials, there are two main hazardous substances in products, including brominated flame retardants and bisphenol A. The content ratio of 4.37% based on the total sales amount of the products, corresponds to the material declaration limit value of IEC 62474 for electrical and electronic products..

Hazardous Substance Survey

Unimicron is disclosing hazardous substances to its customers by means of supplier hazardous substance surveys. After informing suppliers of the new hazardous substance control items, Unimicron requires suppliers to provide a letter of assurance of non-use of banned and restricted substances and a declaration of REACH compliance to ensure compliance with the law and Unimicron's regulations, and to keep track of the use of all materials containing banned and restricted substances and SVHCs. According to the customer's material number that uses SVHC, we reply to the customer survey form and implement source management. In 2022, we cooperated with customers in the investigation of hazardous substances of PCB and Carrier SBU in Taiwan, we conducted a total of 387 supplier surveys, with a response rate of 100%, and completed a total of 818 surveys of hazardous substances required by customers, with a completion rate of 100%.

Reduction Plan of Hazardous Substances in Products

Improvement Plan

In order to enhance product safety, Unimicron is committed to reducing the environmental and human health hazards of the substances in our products. For example, Bisphenol A (BPA) is a chemical substance regulated by international standards and Taiwanese government regulations. To reduce the impact of hazardous substances on the environment, the products of PCB II SBU are 100% compliant with REACH SVHC for BPA concentration. The products of Carrier SBU contain Bisphenol A (BPA) under REACH SVHC according to the customer's specified substrate. If the concentration of BPA in the finished product is higher than the standard, we must notify the customer in accordance with REACH requirements.

Substitution Plan

The Carrier SBU and PCB II SBU have implemented substitution programs and phased out Cobalt (II) chloride (wetness indicator card and desiccant in packages), Arsenic trioxide and Arsenic pentoxide.

2.Process Management

- Test incoming materials and products for Hazardous substances by XRF analyzer. There are 6 XRF analyzers to control the Hazardous Substances of incoming materials, products and package materials.

- "Halogen-free" and "lead-free" are used for the entire production process unless specified by the customer.

- Identify and manage customers' specified materials from incoming materials, receiving materials, and manufacturing to warehousing of finished products.

Operational Chemical Safety Management

order to strengthen the safety management of chemical operations, Unimicron has drafted the "Chemical Management Regulations" to regulate the chemical safety in each plant from purchase, unloading, handling, disposal, use, storage, labeling, Chemical Dispense System Operations, etc. The following are the relevant measures:

| Mechanism |

Measures |

2022 Results |

| Chemical Risk Control |

- The "Priority Management Chemicals" or "Controlled Chemicals" used in the plant are regularly inventoried and audited every year that are reported on the OSHA platform to obtain the reporting certificate to comply with Chemical Substances Registration of government.

- All chemicals are stored in secondary containers to prevent leakage or spill.

- All chemicals stored at the line are limited to one day's usage.

- All drums/tanks are stored in secondary containers (such as dikes, spillage trays, etc.) and are set at 110% of capacity to prevent chemical leaks or spills.

- Emergency showers and related first aid kits (such as Diphoterine, etc.) are installed.

|

- Inventory taking the Group-wide chemicals, there were 750 priority management chemicals and no controlled chemicals. In 2022, all 13 factories in Taiwan completed the declaration before September 30, 2022.

- All chemical storage requirements have been standardized and included in the daily management items of the factory, with 100% completion of inspection.%

- In addition to emergency showers, as required by law, Diphoterine have been installed in high-risk areas, with 100% completion rate.

|

| Safety Regulations for Tank Car Loading/Unloading Operation |

- Software Management: Regular independent inspection of liquid leakage sensors in the tank area, unlocking of tank car by authorized personnel before operation, wearing acid and alkali-resistant chemical protective clothing when supply operations, and checking by authorized personnel after chemical supply.

- Hardware Protection: Establish protection mechanisms for the tank, liquid level control, dosing tank, filling port, etc.

|

- It specially set up inspections for tanker loading/unloading operations, and 624 inspections were completed in 2022. All inspection deficiencies were about chemical management and legal requirements, which all have been improved, and the degree of compliance is 100%.

- The Company has completed 11 plant improvements in 2022 for the tanker filling protection mechanism.

Filling Port:It is designed with "1 Chemical, 1 Box", and set up by zone according to the hazard characteristics and restricted by using non-combination locks, universal locks and universal keys to avoid mistakes in dosing.

Dosing Process:It is controlled by an electric pump with independent power supply, and chained break with liquid level monitoring, and monitor is installed to avoid forced supply or abnormal situations.

Personnel Safety:Personal protective gears, wheel chocks and related emergency response facilities (e.g., fire extinguishers and liquid-absorbing cotton) should be put on during the dosing process, and liquid collection ditches should be set up in the area to avoid the safety risk of personnel.

|

| Chemical Dispense System (CDS) in New Plant |

- Occupational Disasters Prevention: Planning the automatic Chemical Dispense System, designing the storage cabinet and electric control switch for different types of medication with leakage protection to reduce the risk of electric induction.

- Fire Prevention: According to the acid/alkali nature of chemicals, storage is divided into layers to reduce the risk of the reaction of chemicals.

- Chemical Accident Prevention: Preventive measures such as automatic Chemical Dispense System and foolproof design mechanisms are established.

|

- The new plant (Shanying II, Yangmei Plant) was built 100%.

- Other new plants are being built.

|

| Workplace Monitoring |

- Every half year, each plant aggregates speciality chemical, organic, dust, noise, lighting and other items and checkpoint locations to monitor the workplace environment and ensure employees' safety.

- Regularly announce the workplace-monitoring plan and monitoring results every half year.

|

- In 2022 physical and chemical factors were monitored at 4,912 positions, with 22 abnormal positions, all of which are physical factors (noise) exceeding the standard, and the current dealing is to strengthen the wearing of earplugs first.

|

| Health Examination |

- Employees complete regular general and special health checks every year.

|

- Please refer to Chapter 6.4.

|

| Personal Protective Equipment |

- Develop specifications for Personal Protective Equipment (PPE) in accordance with international standards or CNS, and evaluate the comfort and applicability of use.

- Formulate the type and quantity of PPE to be equipped at each workplace.

- Promote and check the use of equipment from time to time at the workplace to ensure implementation.

|

- In 2022, the specifications, types and on-site use specifications of 7 types of personal protective equipment (hard hats, backpack safety belts, rear-opening gowns, acid and alkali-resistant gloves, cut-resistant gloves, safety shoes, and goggles) will be formulated.

- Cooperate with the factory’s three reality checks and the headquarters audit to confirm the usage status, with a factory implementation rate of 100%.

|

| Chemical Detection Systems |

- Install fixed gas detectors and alarm devices in speciality chemical gas workplaces to ensure on-site operational safety.

- Annual inspection, maintenance, repair, testing and calibration of the detector function.

|

- 330 units installed erected in the factory, and 24 new units installed in 2022, to be included in the unified management and control of the factory’s instrument calibration room.

|

3.Product Testing

To ensure that the products produced by Unimicron comply with the green product standards, we not only test incoming materials and products for Hazardous substances by XRF analyzer but also sample products to third-party for hazardous substance testing every year to ensure that the products meet the hazardous substance management requirements. In 2022, the Carrier SBU focused on the 10 substances of RoHS, including halogen (F, Cl, Br, I), antimony (Sb), beryllium (Be), perfluorooctane sulfonate (PFOS), perfluorooctanoic acid (PFOA), Phthalates (DINP, DNOP), Hexabromocyclododecane (HBCDD). The PCB II SBU focused on 10 substances of RoHS and halogens (Cl, Br). Please refer to the ESG website for test reports.

| Analysis Type |

Analysis Item |

RoHS |

Halogen-Free Specification |

Others |

| Third-Party Inspection |

Finished products |

Cd, Pb, Hg, Cr6+, PBBs, PBDEs, BBP, DBP, DIBP, DEHP |

Br, Cl |

Sb, Be, PFOS, PFOA, HBCDD, DINP, DNOP |

| X-Ray Fluorescence (XRF) Analysis |

Raw materials, finished products, packaging materials |

Cd, Pb, Hg, Cr |

Br, Cl |

Sb, As |

Finished Goods Inspections

To ensure that the products produced by Unimicron comply with the green product standards, we sample products to the third party for hazardous substance testing every year to ensure that the products meet the hazardous substance management requirements. In 2021, the Carrier SBU focused on the 10 substances of RoHS, including halogen (F, Cl, Br, I), antimony (Sb), beryllium (Be), perfluorooctane sulfonate (PFOS), perfluorooctanoic acid (PFOA), DINP, DNOP, Hexabromocyclododecane (HBCDD). The PCB II SBU focused on 10 substances of RoHS and halogens (Cl, Br). Please refer to the following files.

Finished Goods Inspections

2024 Product Test Report

2023 Product Test Report

2022 Product Test Report

The list of international directives list

| # |

Regulations/Codes/Standards |

No. |

Release Date |

| 1 |

The Restriction of the use of certain Hazardous Substances in electrical and electronic equipment, RoHS

|

2011/65/EU

(EU)2015/863 | 2011/7/1

2015/6/4 |

| 2 |

Registration, Evaluation, Authorization and restriction of Chemicals, REACH

|

(EC) No

1907/2006 | 2022/1/17 |

| 3 |

Waste Framework Directive, WFD (include Substances of Concern In articles as such or in complex objects (Products)

|

(EU) 2018/851 | 2018/6/14 |

| 4 |

and Packaging Waste, PPW

|

2013/2/EU | 2013/9/30 |

| 5 |

Persistent Organic Pollutants, POPs

|

(EU) 2019/1021 | 2019/6/19 |

| 6 |

Toxic Substances Control Act, TSCA

|

40 CFR 751.401-

751.413 | 2021/3/8 |

| 7 |

End-of-life Vehicle, ELV

|

EU 2000/53/EC

EU 2002/525/EC | 2000/10/21

2002/6/27 |

| 8 |

Global Automobile Declarable Substance List(GADSL)

|

VGADSL

REFERENCE LIST | <2022/><2/><1> |

| 9 |

ENVIRONMENTAL PROTECTION AGENCY OFFICE OF ENVIRONMENTAL HEALTH HAZARD ASSESSMENT SAFE DRINKING WATER AND TOXIC ENFORCEMENT ACT OF 1986

|

Prop65 | 2022/2/25 |

| 10 |

Rotterdam Convention Declaration

|

|

2004/2/24 |

| 11 |

IEC 62474 Material Declaration for Products of and for the Electrotechnical Industry

|

|

|

Note 1:

- Level 1: The substances and/or their purposes classified at this level those whose use must be banned immediately.

- Level 2: The substances and/or their purposes classified at this level those for which a period for phase-out is individually set.

- SVHC:Substance of Very High Concern, Registration, Evaluation, Authorization and Restriction of Chemicals.

Note 2: Waste Electrical and Electronic Equipment (WEEE) not be suitable for Unimicron cause the products made by Unimicron are not end-user products.