Business Continuity and Risk Management

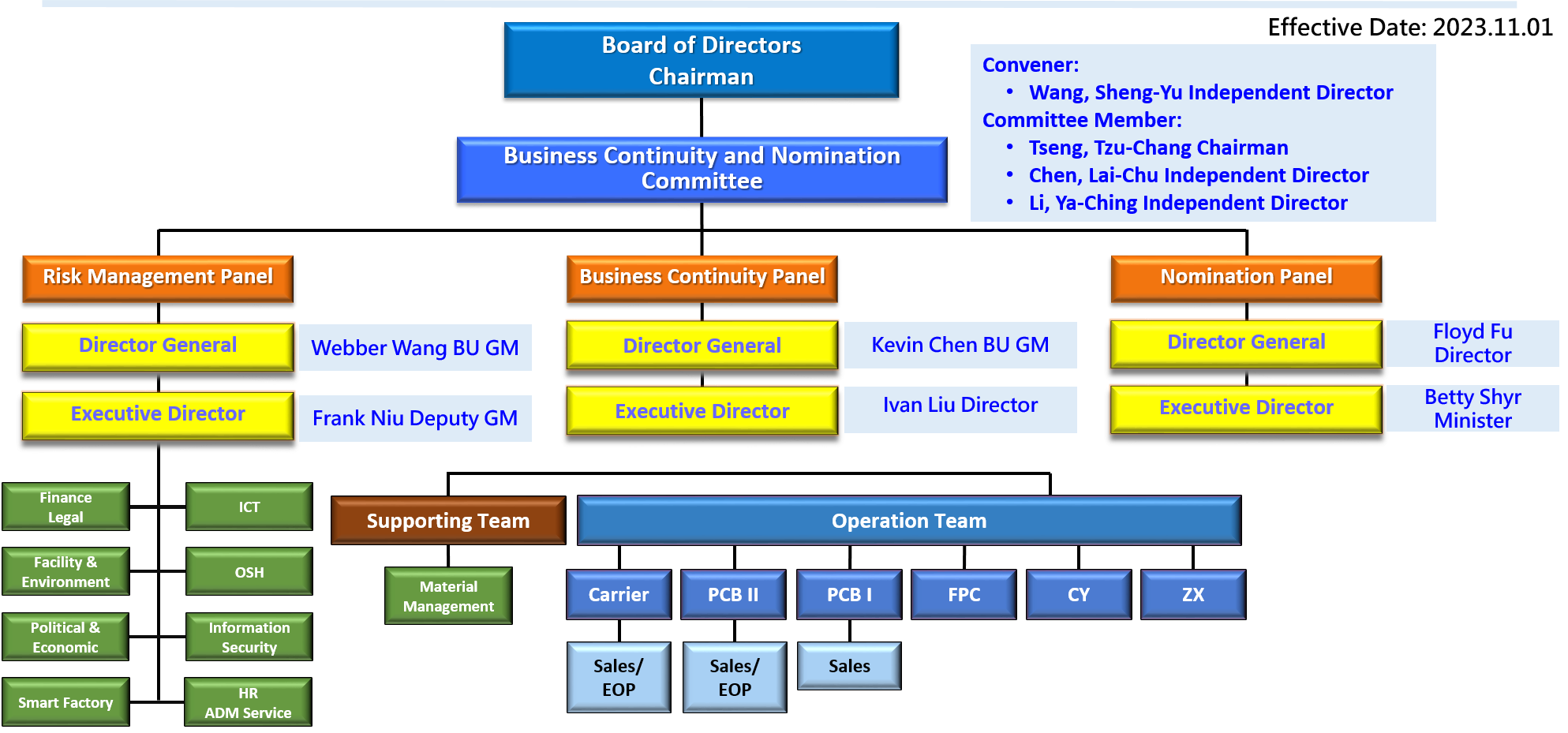

In response to various risks that may cause major operational impacts and demonstrate the operational capabilities of corporation and pursue the sustainable operation, Unimicron established the "Business Continuity and Risk Management Committee" in 2021 to oversee the operational matters related to business continuity and risk management. In order to strengthen the management mechanism, improve corporate governance, and set up a thorough business continuity and risk management system, Unimicron reorganize the "Business Continuity and Nomination Committee" in 2023, which consists of the "Risk Management Panel", "Operational Continuity Panel" and " Nomination Panel".

The members of the committee are appointed by the directors. There are more than 3 members, and half of them are independent directors. All members elect an independent director as the convener.

The functions of the committee are as follows: 1. Coordinate and supervise the corporate business continuity management in the emergency event of major accidents or disasters, to prevent potential losses and minimize likely impacts, so as to protect the right and stakeholder. 2. Integrate management to respond to various risks that may have an impact on operation, and coordinate company-level information technology protection mechanism. 3. Formulate the selection criteria and succession plan for senior managers, select and review nomination candidates. 4. Build and develop the organizational operation of committee, plan and implement the performance evaluation of senior managers.

Business Continuity and Risk Management Panel regularly reports to the Board of Directors biannually. In order to prevent and control corporate risk effectively, we have established the "Business Continuity Management and Risk Management Policy" approved by the Board of Directors. The relevant risks are dealt with in accordance with departmental authorities and responsibilities. We periodically perform risk assessment, risk mitigation, and follow-up review, formulate and adopt corresponding risk management program to enhance the resilience of sustainable management.

Operational Situation: Unimicron's Business Continuity and Nomination Committee held the first meeting of its first term on December 19, 2023, and explain the organizational function and responsibilities of the Risk Management panel and the Business Continuity Management Panel and planning matters.

Note: Discussed and approved by the Board of Directors on October 23, 2023.

Business Continuity Management & Risk Management Policy

Unimicron, through the three main pillars of “Caring for the Planet, Respecting People, and Pursuing Performance” creates positive value for employees and all shareholders, and gradually implements the corporate vision of a “world-class, high-tech Company with high value-added, high quality, high productivity and emphases on innovative service” and “pursuing the satisfaction of customers, employees, and shareholders and fulfilling their responsibilities,” taking into account the sustainable growth of enterprises as the highest purpose of continuous management. Committed to proactively maintaining risk and crisis management, through the operation of business continuity management organization, the implementation of operational impact analysis and risk assessment in the event of changes in the operating situations, based on the formulation of operational continuity strategies, objectives, and contingency mechanisms, adequate resources to support and implement, continue to review and improvement. When disasters or shocks occur, in accordance with the operational strategy of rapid response, maintain and resume operations, to keep good communication with customers and stakeholders, and ensure their best interests.

Note: Policy discussed and approved by the board of directors on December 19, 2022.

| Scope of Risk Management |

Risk Management Mechanism |

Operation |

- Operational Risk:The risk of uncertainties in the Company's operations affecting normal operations, such as material shortage or improper production scheduling, product quality risk, labor dispute risk, and information system risk.

- Financial Risk:Financial and business risks caused by economic and industrial changes, such as interest rate, exchange rate, liquidity and credit risks.

- Strategic Risk:Losses caused by wrong strategies, such as over-concentration of sales territories, over-concentration of customers and mergers and acquisitions.

- Hazard:The risk of loss caused by major natural or man-made disasters (such as Climate change, earthquakes, fires, chemical spills and epidemic infectious diseases).

- Compliance Risk:The potential loss resulting from failure to comply with government regulations.

|

- Risk Assessment and Risk Mitigation:Review various potential risks every year, classify them and score them according to the established risk index. Then, prioritize mitigation and response plans for those with higher assessed risks. To avoid the losses caused by risks, Unimicron has purchased a complete variety of insurance (such as property insurance, operation interruption insurance, installation engineering insurance, cargo transportation insurance, product liability insurance, etc.) to ensure that when risks occur, Unimicron still has sufficient capacity and resources to carry out subsequent operation restoration, and indeed to fulfill all commitments to our customers.

- Contingency Plan:In response to a major disaster, Unimicron has formulated the organization and resource planning of the corresponding crisis management team, and established a contingency plan to enhance response efficiency shorten recovery time and reduce the impact on operations after the event.

- Drill and Continuous Improvement:Each department conducts a single or comprehensive drill in accordance with the plan or other unexpected situations and makes recommendations for review and improvement. Through regular drills, point inspections, and mutual support of group resources, we could ensure continuity of operation within the maximum scope under a state of distress, minimizing the affected time and impact.

|

2021

Establishment of the Business Continuity and Risk Management Committee. Formulation of the “Business Continuity and Risk Management Policy”.

Formulation of the “Constitution and Operation of the Business Continuity and Risk Management Committee“.

Establishment of “Risk Management Procedure” for each division to conduct risk assessment and prepare mitigation plans.

2022

Completed risk assessment and mitigation plan.

For COVID-19, the Material Management Division conducted the investigation, evaluation, and management of suppliers following the "Procurement Risk Management Procedures". There were no incidents affecting production.

Reported to the Board of Directors. 2023

Established the "Business Continuity and Nomination Committee" organization, which consists of various functional panels: risk management panel, operational continuity panel, nomination panel.

Each unit needs to complete risk assessment and the update of mitigation plans.

Report operational results to the Board of Directors. |

Risk Response

Among the past three fire incidents, the fires at the China Plant on September 7, 2020 and the Taiwan Plant on February 4, 2021 were both caused by improper fire control during construction. The cause of the October 28, 2020 fire at the Taiwan Plant was investigated by the competent authority as a problem with the exhaust system, which is more likely to be the cause of the fire. In response to the three fire incidents, we have proposed improvement measures for fire prevention and personnel response in the factory, and have been tracking and reviewing the progress of the improvements regularly. The fire-related risk control mechanisms could see the below:

| Type |

# |

Mechanism |

Improvement |

| Organization |

1 |

Hire external experts to enhance emergency response and risk reduction solutions |

- 1. Hire Captain Chung from UMC Fire Department to provide guidance on emergency response and damage prevention techniques.

- 2. Establish communication channels with government fire departments and conduct regular contingency drills and training.

- 3. Establish a channel for insurance companies to consult on Loss Control techniques and conduct regular surveys.

- 4. Provide guidance on damage prevention techniques through professional consultants.

- 5. Join the industrial area joint defense organization and regularly practice regional drills.

|

| System |

1 |

Regularly review the risks and opportunities of the ISO 45001 management system and achieve the OSH objectives on an annual basis |

- 1. Hazard identification & Risk Assessment.

- Review the hazards of the workflow and position.

- List of unacceptable risks and improvement opportunities.

- 2. OSH target implementation.

- Convene management review meeting to decide the above items.

- Set up and implement occupational safety and health targets.

- Convene an OSH committee to regularly track the progress on Implementation.

|

| 2 |

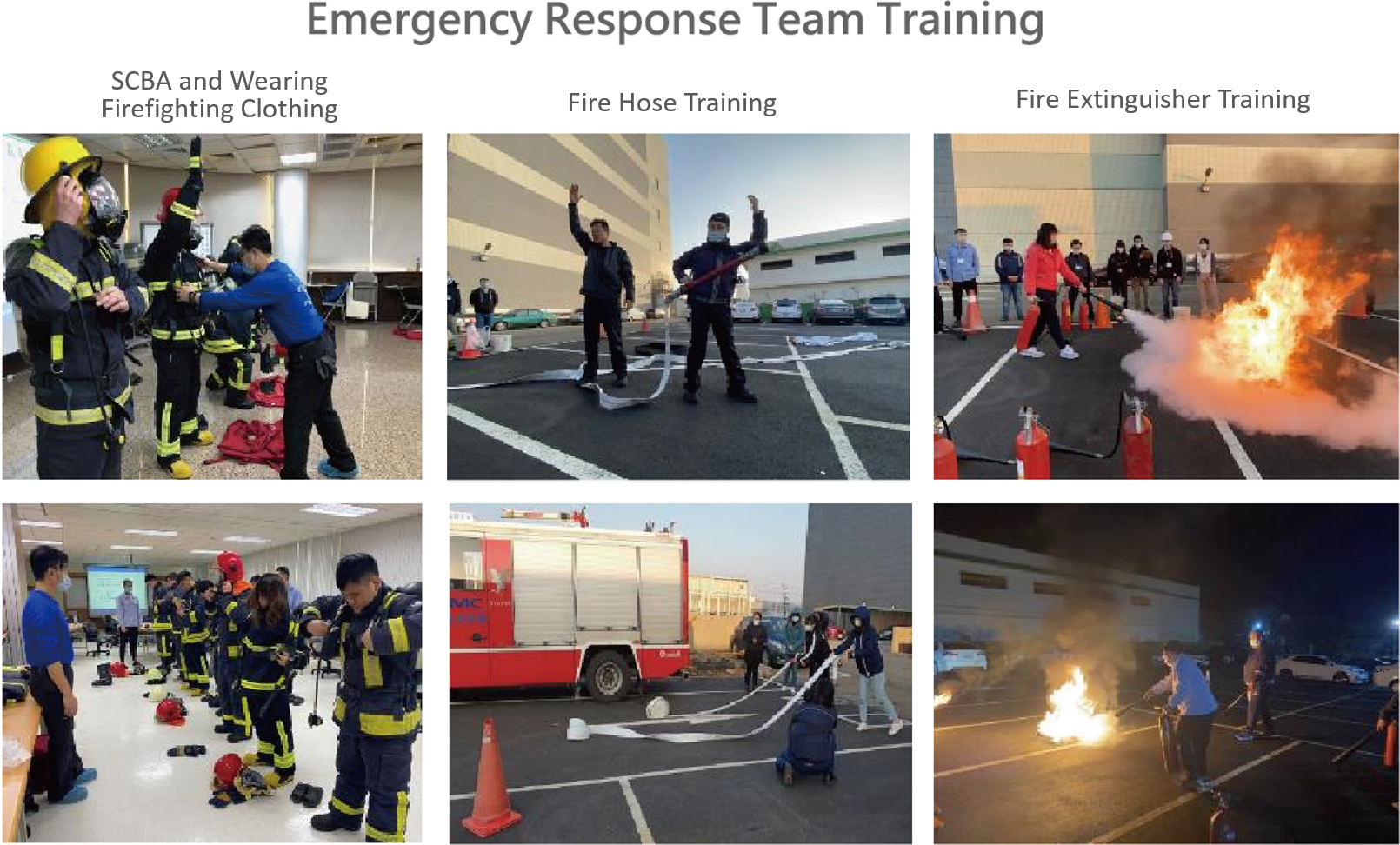

Establish an emergency response system and strengthen the emergency response capability within the plant |

- 1. Establish Management System.

- Establish a plant/class level emergency response structure.

- Optimize emergency response procedures.

- 2. Strengthen Emergency Response Capability.

- Establish the emergency response team (ERT) and conduct regular training.

- Enhance the ability to find abnormalities on site and provide first-time disaster relief.

- Strengthen the response capability of the command system on site.

- 3. Prepare Contingency Equipment: Standardize contingency equipment and implement regular inspections.

- 4. Implement Fire Drill: Implement plant level and class level fire drills biannually.

|

| Operation |

1 |

『Short-Term』– Establish Loss Control Safety and improvement plans to reduce operational risks |

- 1. Heat exhaust duct was changed to independent heat exhaust duct made of metal.

- 2. The PP exhaust duct above the air-conditioning room was changed to UL 94 Standards V-0 flame retardant.

- 3. Strengthen the demarcation of fire protection areas across the bridge to improve the fire protection capability of the building.

- 4. Store chemicals on site for one-day use only.

- 5. Strengthen the Hot Work permit system and on-site hot work operation management.

- Improve safety control before, during and after construction.

- Designated Hot Work area in the area that is often required.

|

| 2 |

『Long-Term』– Establish Loss Control Safety and improvement plans to reduce operational risks |

- 1. Improve process system ≧ 10" acid/alkali plastic ducts to reduce the fire risk.

- New construction/reconstruction: Ducts changed to metal with corrosion-resistant coating..

- Existing plant: automatic water spreading system in ducts.

- 2. Automatic fire extinguishing system and very early warning system in high-risk areas.

- 3. The wet process introduces hot water or steam heating type, and the electric heating type shall be with a double safety interlock device.

- 4. The insulation materials (foam) for chilled/cooling water and high-temperature heat exhaust pipes are changed to the flame-resistant materials (FM 4924).

|