Sustainable Supply Chain

| Topics |

Sustainable Supply Chain |

| Policy |

- Fulfill the Responsible Business Alliance’s “RBA Code of Conduct” as the basic principle for conducting business activities

|

| Commitment |

- Sustainability and co-prosperity, providing total quality that meets customers’ satisfaction

|

| Division |

- ESG Committee

- Supply Chain Subcommittee

- Sales, Customer Service, Materials Management Division and Quality Management Division

|

| Resources Invested |

- Organize a supplier conference

- On-site audit of CSR suppliers and deficiency counseling materials

- Daily advocacy

|

| Grievance Mechanism |

- whistleblower hotline and mailbox

|

| 2022 Targets |

- Upstream and downstream supply chain management meeting the requirements of quality/cost/delivery/service/technology and CSR management system and fulfillment of CSR commitments

|

| Actions |

- Meet customers’ requirement

- Advocacy to suppliers/Supplier evaluation/Supplier audit/Supplier assessment

|

| 2022 Achievements |

- The completion rate for signing Supplier Corporate Social Responsibility Commitment Letter: 96%

|

Supply Chain Overview

Unimicron’s suppliers mainly include seven categories of raw material suppliers, equipment, engineering suppliers, waste disposal companies, on-site companies (such as security), human resources brokers, and land, sea, and airfreight forwarders. Which, both raw material and equipment suppliers in Taiwan are the most important supplier categories, totaling 582 companies. For the major raw material suppliers and equipment suppliers (including strategy key suppliers) involved in the manufacturing of our products, we have developed sound quality management and CSR management model for corporate social responsibility, financial risks, conflict minerals, and Business Continuity Plan to meet the principles of corporate sustainable development. At the same time, we have established positive partnerships with suppliers to oversee their CSR-related risks, strengthen audit management, and coach and assist in improvement, all to lead the overall supply chain toward a sustainable future.

Unimicron follows customers’ requirements and is committed to the improvement and refinement of the CSR management system. In addition to self-requirements, it also hopes that suppliers can co-prosper and maintain sustainability with Unimicron. Regarding the risk management of sustainable business operations, in addition to the continuous implementation of supply chain management, we began to include the RBA Code of Conduct, regulations and other supply chain potential risks in the assessment items at the end of 2018. The mitigation plan for high-risk factors is included in the mandatory targets of the Material Division, and continuous improvement and monitoring have been carried out to meet the targets.

Sustainable Supplier Management

Unimicron promises to establish a supplier management system and specifications and communicate with them every year to establish a stable and sustainable development of a win-win strategic partnership. To promote the sustainable management of suppliers and build a more resilient supply chain, Unimicron has included aspects of ESG policy, RBA Code of Conduct, supply chain continuity operations, finances, conflict minerals, etc. in the sustainable supply chain management issues and jointly mitigates supply chain risks. In addition, a cross-departmental “Supply Chain Management Subcommittee” assists suppliers in improving and upgrading quality systems, environmental protection, green procurement, safety, human rights, ethics and supply chain, and building supplier sustainability.

Unimicron integrates the management system with the procurement process in promoting sustainable supplier management, and requires raw material and equipment suppliers to sign a "Supplier Corporate Social Responsibility Commitment Letter". The content of the commitment letter is based on the RBA Code of Conduct, the International Labor Organization Convention, and the Social Responsibility SA 8000 standards, and the content covers ethics, human rights, the environment, and health and safety considerations.

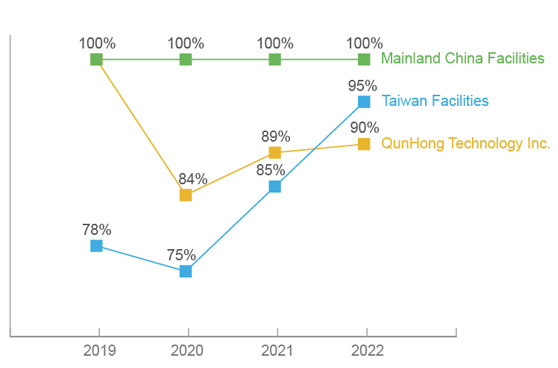

Signature Rate of Supplier Corporate Social Responsibility Commitment Letter

Aspects of the Supplier Corporate Social Responsibility Commitment Letter

- Business ethics compliance statement

- Statement of social responsibility

- Warranty of non-infringement

- Environmental hazardous substances non-use declaration

- Commitment to the non-usage of illegally mined raw materials

2022 Supply Chain Management

Local Procurement

Unimicron adheres to the principle of sustainable corporate social responsibility and hopes to promote the sustainable development of the entire supply chain. Therefore, to promote operational activities and local economic development, Unimicron actively implements localization of materials and supports the development of local suppliers, all to reduce unnecessary air and water freight costs, as well as the carbon footprint generated during material transportation. In 2022, the local procurement ratio of raw materials purchased by Unimicron in Taiwan was 69%. QunHong Technology Inc. had a local procurement ratio of 91%, and Mainland China Facilities had a local procurement ratio of 81%. The local procurement amount of the Taiwan Facilities in 2022 decreased by 3% compared to 2021, mainly due to the change in product structure and the increase of high-end products, which influenced the increase of the procurement amount of major materials imported from abroad. Although the local procurement amount decreased in 2022, the Taiwan Facilities have actively communicated with an important Japanese substrate supplier partner in recent years to set up a plant in Taiwan, and the substrates originally purchased directly from Japan have been partially produced and delivered from the plant in Taiwan. The contribution rate of the purchase amount increased by 66%, compared with 2021.

Percentage of Local Procurement Amount

(Unit: %)

| Year |

Taiwan Facilities |

QunHong Technology Inc. |

Mainland China Facilities |

| 2019 |

67 |

81 |

84 |

| 2020 |

73 |

83 |

84 |

| 2021 |

72 |

87 |

84 |

| 2022 |

69 |

91 |

81 |

Note: Local scope includes local suppliers and Taiwan agents.