Complaint Mechanism and Handling

Unimicron pays considerable attention to the opinions given by our customers. We view customer complaints and comments as opportunities to assist us in continuous improvement. Thus, Unimicron has built a complete mechanism to ensure the effective communication, processing and response of customer complaints and opinions through a comprehensive, systematic and standardized processing procedure, in order to protect customer rights and interests.

Customer Quality Complaint Acceptance and Processing

Situation Monitoring and Response

Analysis and Improvement Regarding Customers Complaints

Abnormality Correction Reply Report

Follow-Up on the Effectiveness of Improvement and Information Management

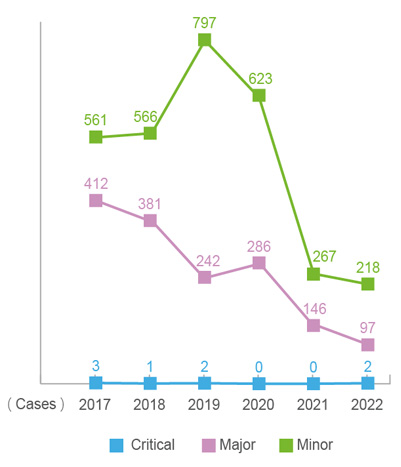

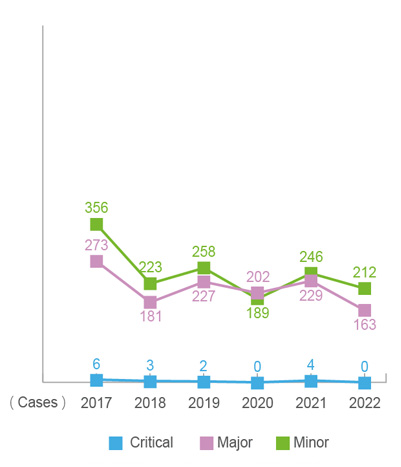

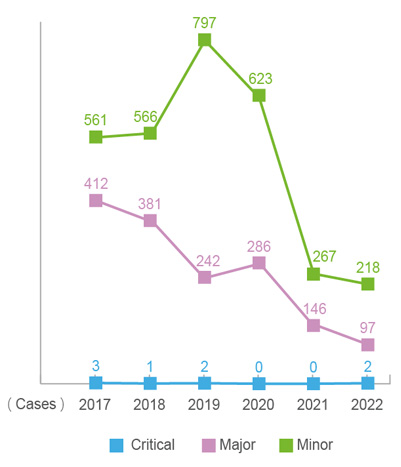

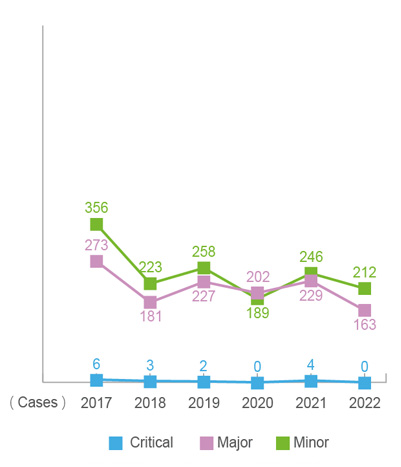

Unimicron categorized customer complaints into three types - “Critical”, “Major” and “Minor” - based on their severity level, with which the cases are reported, handled and have their progress tracked accordingly. It is expected that all complaints can be handled and responded to properly, with the most efficient use and allocation of resources. 100% response to customer complaints received in 2022.

Customer Complaint Notification and Management

Explanation for 2022 Customer Complaint

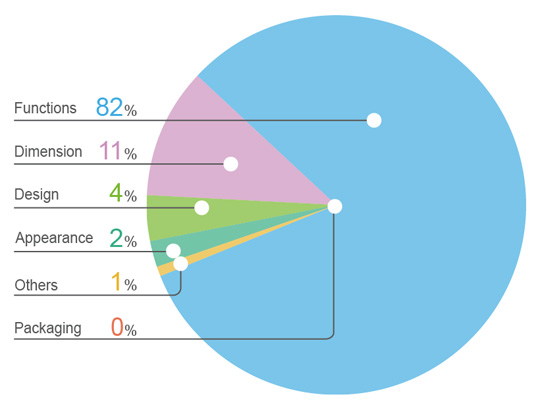

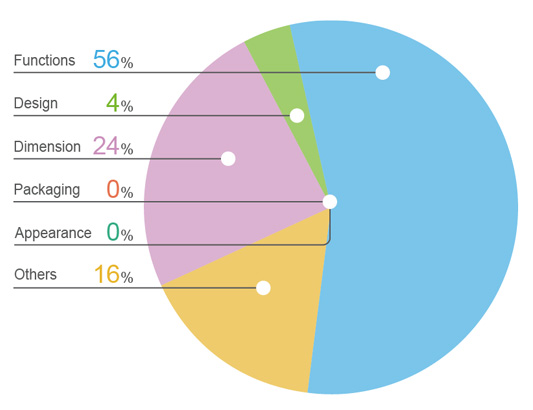

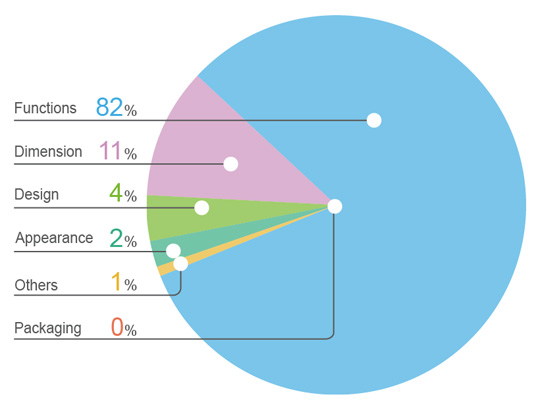

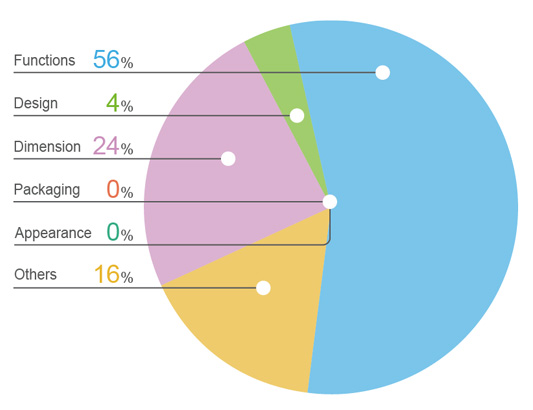

2022 Customer Complaint Issues

PCB SBU

Carrier SBU

Customer Complaint Trend for PCB SBU Products

Customer Complaint Trend for Carrier SBU Products