Occupational Safety and Health

Unimicron is committed to providing employees with a quality, safe, healthy and comfortable workplace, which includes production and non-production areas and routine and non-routine operations in employment sites under our purview, plus the operations of all external stakeholders (including food suppliers, raw material suppliers and contractors) entering Unimicron’ employment sites as well as facilities and equipment provided by external units operating in the premises of Unimicron plants. In order to improve the overall operating effectiveness of OSH organization, we established the Occupational Health and Safety Division in 2021, and have continued to invest resources and promoted various actions. In 2022, aiming at strengthening the fire protection function and improving the fire risk management and control mechanism, the Company ensured fire safety, to demonstrate the Company's continuous refinement and improvement of the occupational safety management system.

2012.01

Unimicron’s Taiwan Facilities have passed TOSHMS certification

2019

Taiwan Facilities completed the conversion certification of OHSAS 18001 to ISO 45001

Mainland China Facilities have completed the conversion certification before March 2021

2020

Unimicron won the 2020 National Occupational Safety and Health Award issued by the Ministry of Labor

2021

In order to improve the overall operating efficiency of our occupational safety organization and actively implement monitoring and control, the Occupational Safety & Health Division was established.

2022

Set up a professional fire-fighting team in 2021, strengthen and improve the fire-fighting mechanism in 2022, and establish Emergency Response Teams (ERTs) in all plants.

Safety and Health Resource Input

Note: We invested funds in the maintenance and inspection of hardware and facilities, the addition of equipment, education and training, and the verification of the management system. The exchange rate for RMB : NTD = 1 : 4.4144, quoted from the National Taxation Bureau of Taipei.

2022 Achievements

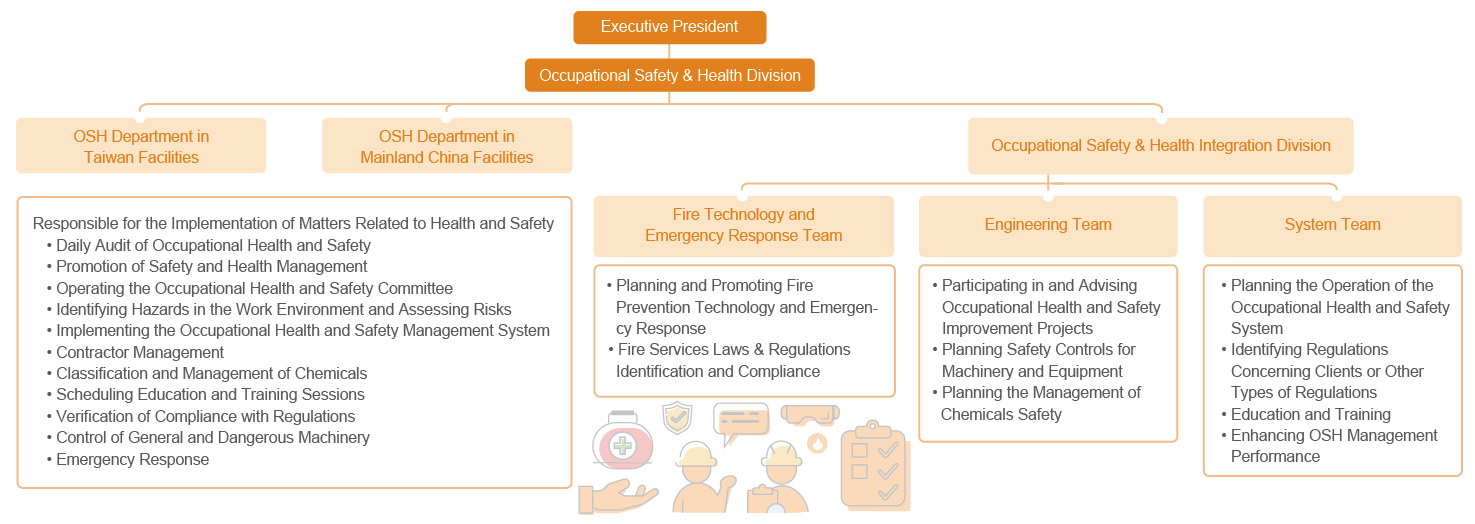

OSH Management Organization

The International Certification

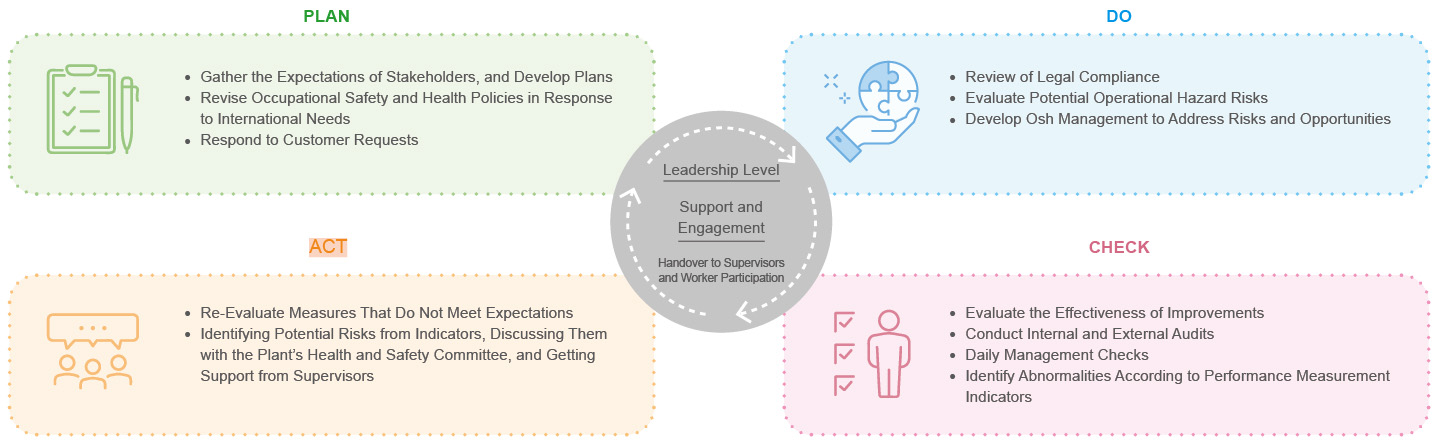

A comprehensive Occupational Health and Safety Management mechanism is built on the spirit of self-management and systematic actions. Therefore, we actively introduced the ISO 45001 Occupational Health and Safety Management System at each of the plants and implemented the spirit of PDCA continuous improvement through the e-management interface to enhance the effectiveness of the management system.

Management Organization

All OSH management personnel in each of Unimicron facilities are full-time permanent personnel, and all Taiwan facilities have established OSH management units and personnel in compliance with “Occupational Safety and Health Act” and relevant regulations; the person in charge of each workplace and supervisors at all levels will direct and supervise the implementation of safety and health management matters according to their responsibilities and powers following the work items planned by the OSH management unit, and coordinate and guide the relevant personnel to implement. All workers in the Company perform related matters following the OSH management standards.

All employees of the Company are expected to comply with the standards set by the results of the hazard identification and risk assessment process. According to the Unimicron OSH Management Measures, Unimicron would protect workers from revenge that may affect their right to work or promotion during their employment, or protect them from being discriminated against if they report or notify incidents, hazards, risks, or opportunities by written document and Email; leave work conditions that are likely to cause harm or disease; or report hazards or dangerous situations to worker representatives, employers, or regulatory authorities.

To cultivate OSH culture in the workplace, we not only input resources to comply with regulations, but set an Occupational Safety Officer in each unit in each plant to assist in advocacy and implementation of OSH activities, inspect related facilities and equipment, conduct training and related audits to facilitate communication between planning and execution. In 2022, there were 533 Occupational Safety Officers in Taiwan Facilities and Mainland China Facilities, 1 in 47 employees on average in Taiwan Facilities, and 1 in 59 employees on average in Mainland China Facilities.

Unimicron has established the OSH Committee and regularly holds committee quarterly meetings in Taiwan facilities and monthly meetings in Mainland China facilities. Both employer and employees participate in meetings, which involve the requirements of the “Occupational Safety and Health Act” such as communication, participation, consultation, and related matters. The ratio of the labor representatives in the committee is superior to regulatory requirements in Taiwan facilities, with an average ratio of 52% in 2022. The ratio of labor representatives in Mainland China facilities also reached 61%, showing how much we value employees’ opinions and participation

2022 Proportion of Labor Representatives or Occupational Safety Officers

Note:

The Shanying includes Shanying Plant, Precision S1 Plant, Precision S2 Plant, Precision S3 Plant, Shanying Wenhua Plant and Shanying II Plant.

The Hejiang includes Hejiang Plant, Hejiang II Plant and Chungli Plant.

The Luzhu includes Luzhu II Plant and Luzhu III Plant.

The Yangmei includes Yangmei Plant.

The Hsinchu includes Hsinfeng I Plant and Chung Hsing Plant.

QunHong Technology Inc. includes QunHong Dacheng Plant and QunHong Renyi Plant.

Mainland China includes Unimicron (Kunshan), Unimicron-FPC (Kunshan), Unimicron (Suzhou), Unimicron (Shenzhen), and Unimicron (Huangshi).

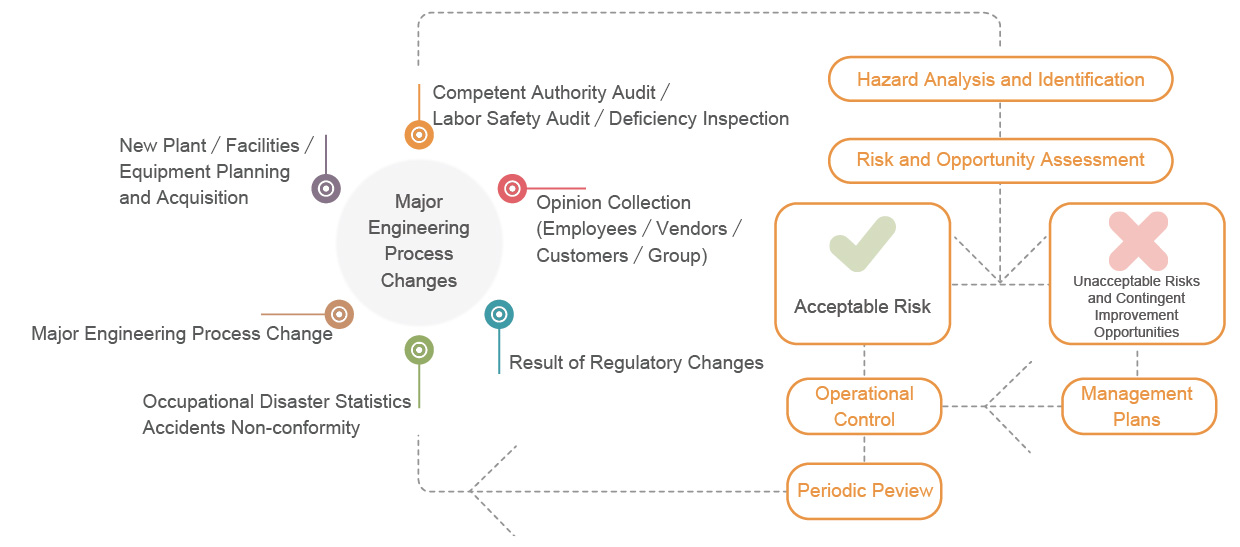

Hazard Identification and Control

All personnel responsible for the Identification of OSH Hazard and Risk Assessment have taken OSH System training and have passed assessments. When any work activity changes or abnormalities occur, they should be able to re-execute hazard identification and risk assessments. If risk assessment is classified as an unacceptable OSH risk (major/high risk) with major negative impacts, there will be an improvement plan based on elimination, replacement, engineering improvement, administrative management, and personal protective equipment to seek the best method of risk reduction and perform continuous improvement.

OSH Hazard Identification and Risk Assessment Operation Process

To avoid work-related incidents, Unimicron continues to implement high-risk work safety assessment and safety observation and evaluation in all Facilities, strengthen occupational incident prevention and improvement projects, and educate and strengthen employees' awareness of self-safety. There are 64 types of specific hazardous workplaces, including noise, ionizing radiation, manganese, lead, nickel, and fine dust in Unimicron Facilities in Taiwan and Mainland China, and regular specific workplace health examinations are carried out every year. After assessment, there were no cases of occupational diseases as defined in the regulations in 2022.

2022 Health Examination and Occupational Disease Prevention and Control

Taiwan

- Special Health Examination: 5,778 people

- Second-Level Management of Special Health Examination: 4,384 have completed health education courses

- Fourth-Level Management of Special Health Examination: All 54 employees with abnormal hearing have been interviewed by the on-site physicians to complete the reconfirmation of work competence

- Management Measures: For areas that are noisy, regular environmental tests are conducted every six months. If the noise level exceeds 90 decibels in the work area, sound-absorbing foam will be installed to control noise levels and personal protective gear will be provided. For management staff at Annual Noise Level 2 or above, training is provided; for management staff at Noise Level 4, on-site assessments by occupational medicine specialists will be arranged, and one-on-one interviews will be conducted to control hazards, adjust work content, or change work hours based on the results of the interview.

Mainland China

- Special Health Examination: 4,616 people

- Employees with Abnormality:71 people, of which 47 were abnormal hearing, 24 were abnormal in other, all of which have been tracked and improved

- Management Measures: The personnel who passed their physical examination before and during their shifts can continue to work as usual; the personnel who receive abnormal results from their physical examination or reexaminations are transferred to different posts, and their results and work duties are analyzed. Most personnel have hearing abnormality in their physical exam results, and the hazardous factor that is causing that issue in their work is noise. Therefore, we take measures to improve job environments that deal with noise, such as equipment noise reduction, enhancing inspections, replacing and repairing equipment immediately as soon as it makes abnormal noises, holding OSH training sessions, using noise detectors, and doing noise inspection in the workplace from time to time.

2022 OSH Improvement Project

2023 OSH Improvement Project

OSH Key Management Projects

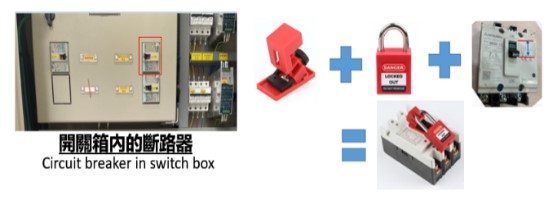

Machine Equipment Safety

Unimicron provides employees with safe machine equipment, from design, procurement, installation, safety inspection, operation safety management and replacement and scrapping, etc., to avoid accidents.

Design, Procurement Specifications

The company has set safety specifications for new machines, equipment manufacturers need to meet the specifications, the labor safety office will conduct safety matters review, if there is any discrepancy, it needs to be improved, before procurement.

Installation Requirements

• Move in:Equipment manufacturers/installers, in accordance with the company's safety regulations.

• Equipment assembly:According to the implementation of the contractor management measures, the authority and responsibility department shall conduct inspections before, during and after installation to ensure compliance with various safety requirements

Safety Inspection

According to the safety specifications of the new machine, the labor safety room and the equipment department jointly carry out safety inspection, and when there are non-conformities, the equipment manufacturer is required to improve within a time limit, and the machine can be handed over for acceptance only after the re-inspection is passed.

Operation Safety Management

- When the machine is running, personnel must wear corresponding personal protective equipment according to SOP.

- All safety interlocks and detection instruments must be tested and recorded regularly.

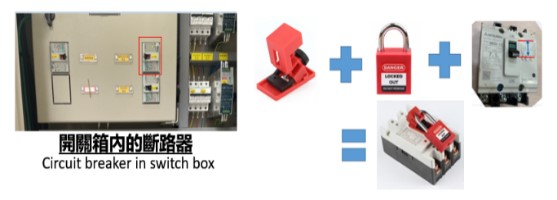

- Implement Lock Out & Tag Out: Equipment must be marked in repair and maintenance, and the power source switch/valve should be locked with a lock to block and shut off the power source to ensure operational safety.

Safety Inspection

Irregular on-site safety inspections are conducted by the labor safety office, supervisors at all levels of the factory and occupational safety offices.

Replacement and Scrapping of Machine Equipment

- Replacement and scrapping:the machine is scrapped, the stop is posted to be disposed of, and the relevant electricity, chemicals and other supply and waste pipelines are blocked and locked.

- Equipment disassembly:Before the equipment is disassembled, it is confirmed that the water, electricity, gas and waste have been blocked, and the dismantler shall carry out the dismantling operation in accordance with the contractor's management measures.

- Move out:The scrapped equipment is handed over to the contractor with a qualified license and implemented in accordance with the relevant regulations of the company.

Operational Chemical Safety Management

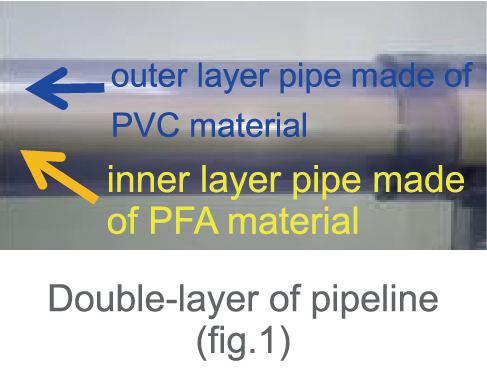

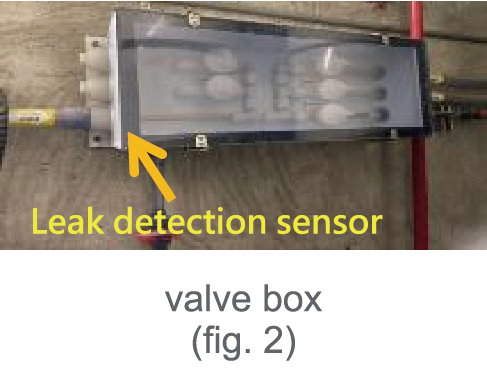

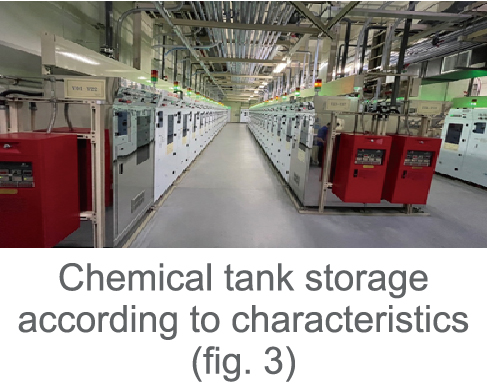

In order to strengthen the safety management of chemical operations, Unimicron has drafted the "Chemical Management Regulations" to regulate the chemical safety in each plant from purchase, unloading, handling, disposal, use, storage, labeling, Chemical Dispense System Operations, etc. The following are the relevant measures:

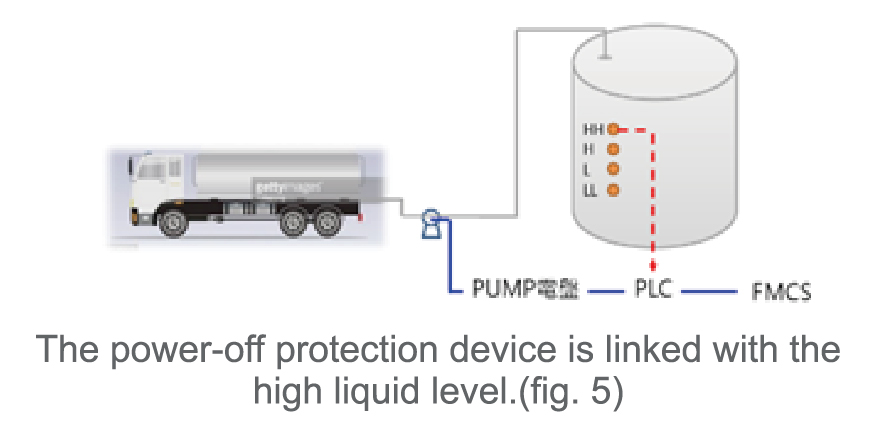

Chemical Detection Systems

Fire Safety and Loss Prevention

There were three fire accidents happened in UNIMICRON recently. Among them, the fire at China Plant on September 7th in 2020 and Taiwan Plant on February 4th in 2021 were both caused by improper hot work control. Moreover, in the fire at Taiwan Plant on October 28th in 2020, the investigation report from local AHJ showed that it was likely caused by the problem with exhaust system of the manufacturing process. In response to these three fire accidents, to ensure the fire safety, the company proactively develop relevant countermeasures, regularly track and review the improvement, strengthen the organizational functions of occupational safety and fire protection, enhance the communication channel with insurance companies or external experts, intensify the fire risk control mechanism, and increase the emergency response capabilities.

Summary For Critical Strategies:

Strengthening the Ability to Prevent Fire Damage

In response to the three fire incidents at Unimicron in recent years, we conducted a review of damage prevention and emergency response, improved on-site equipment and plant facilities, and supervised from daily management to headquarters audits, in order to strengthen emergency organization capabilities and damage risk control.

- Complete safety interlock and overheat protection mechanism for wet process electric heaters and ovens, and require the use of flame-resistant grade or change of process heating method for electric heating tanks

- Regularly organize IR scan professional training to enhance the electrical accident prevention ability of professionals, and strengthen electrical safety through the improvement of detection and tracking prevention.

- Establish an Aspiration Smoke Detector System (ASD) in high-risk areas and partial discharge monitoring in substations.

- Improve the risk of burning acid-base plastic air ducts with process exhaust ≥ 10 inches.

- Set up automatic fire extinguishing equipment in high-risk areas.

- Establish ERT and regular drills for each plant.

- In addition to the daily management of the plant, the Occupational Safety Office conducts audits on damage prevention and emergency response every six months to ensure that the plant implements.

Emergency Response and Drill

Organization Chart

Emergency Response Flow

There are three stages in Fire, Explosion, Chemical Leakage Emergency Response Operations, please see below for general introduction.

The Zero Stage (Notification Response): Call, report and respond through the accident notification process when people discover abnormal conditions or the activation of fire detectors.

The First Stage (Instant Search Response): hen the disaster occurs in one area, and the unit of abnormal area (including firefighting team) and the competent authority are called and notified by the witness to conduct timely search and initial rescue.

The Second Stage (Plant-Level Response): When the disaster spreads from one area to other areas, the unit of abnormal area and the competent authority are unable to control the condition. The plant commander conducts the initiation of emergency response team and takes evacuation action. If the emergency response team cannot effectively control the disaster condition, while the fire brigade is arriving at the scene, the plant commander directly transfers the authority to external unit and assist in providing relevant information.

Training

Each plant has established an Emergency Response Team (ERT), to effectively improve the responders’ on-site search, emergency response, fire-fighting equipment suit and self-contained breathing apparatus (SCBA) wearing, the use of fire hose nozzles, and the response, decision-making and dispatching capabilities. Both plant commander and ERT must finish the relevant professional training courses.

• Standardization on emergency response equipment and fulfillment of regular inspection.

• Establish Emergency Response Team and take refresher training.

• Comprehensively enhance the disaster searching and rescue capabilities.

• Strengthen the emergency decision-making competency of commanders.

Emergency Drill

Emergency Response Drill: The company implements the self-guard fire protection grouping in accordance with national regulations and the company's emergency response operations, and conducts the emergency response evacuation and drills biannually, including disaster scenario simulation, enhancement of logistics support capabilities, the wearing familiarity of emergency response equipment.

Emergency Evacuation: To evacuate people who are not the emergency response team to a safe place in the shortest time, this could avoid being affected in case of disaster extension and even influence the rescue. When people move to the assembly point, the number of personnel must be verified and ensure all internal/ external personnel must be at the safe place.

Enhanced Emergency Response Management

Unimicron implements the self-guard fire protection grouping in accordance with national regulations and the Company's emergency response operations, and conducts the emergency response evacuation and drills biannually, including disaster scenario simulation, enhancement of logistics support capabilities, and the wearing familiarity of emergency response equipment.

We have standardized emergency response equipment and facilities to maintain the functionality of the equipment so that we can be familiar with the use of emergency response equipment and facilities to strengthen the Emergency Response Team (ERT).

Contractor Management

Unimicron Technology Group for the management of contractors in accordance with the relevant requirements of the Occupational Safety Law, from the training of contractors before entering the factory, qualification review, confirmation on before and after construction operations, and evaluation of contractors that meet all the requirements of various laws and regulations. To lessen the risk of construction projects.

1.Description of the Contractor's entry and exit operation procedures

According to the "Administrative Regulations on Contractors", contractors are required to complete contractor education and training and submit relevant materials before entering the factory before they can obtain the Group's Contractor Qualification Certificate. According to the "Management Procedures for Contractors" and "Administrative Measures for Contractors", the factory supervisors must complete the on-site construction safety notice (including the dangerous work permit), and the safety and health agreement organization meeting minutes and other documents before leading the contractor into the factory.

The process of entering and leaving the factory for Contractors

2.Application for Hazardous Work:

The factory area manages high-risk related operations, including through the control of the permit system, so that the Check beforehand, prepare safety facilities, and complete the inspection after the work is completed, so as to prevent safety risks and avoid any accidents.

2-1.Formulate Risk Classification Management for Hot Work:According to the supervision of the hot tool in the factory, the company follows the list of risk classification control specifications for hot work,, together with the unit supervisor, and factory supervisors and factory workers are at the construction site, Confirm before carrying out secondary hot work, After confirming consent to hot work, Sign on the hot work permit to confirm, The contractor enables hot work to be carried out.

2-2.Hazardous Operation Process:

3.Contractor's Safety Operation Inspection:

Perform safety and health inspections, audits and records of contractors' operations in the factory from time to time. If any deficiencies related to contractors are found, it will be recorded in the contractor's operation inspection record sheet. If the hot work is performed in the factory, there is also a supervisor inspection record sheet for the contractor's hot work operation, so as to implement the management and control of the contractor's inspection work.

4.Contractor Evaluation Work Specification:

In response to the implementation of the group's occupational safety and health system, it is planned to conduct a survey of "Occupational Safety and Health Management Evaluation" for contractors to audit the effectiveness of each contractor's cooperation in implementing occupational safety and health management system activities and various construction safety, The contractors are graded as A, B, C and D according to their scoring criteria. Unqualified manufacturers are not allowed to be included in the list of qualified suppliers.

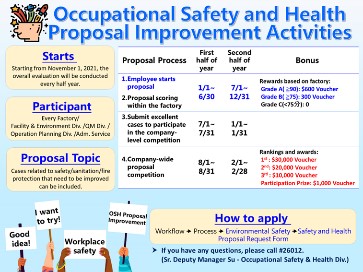

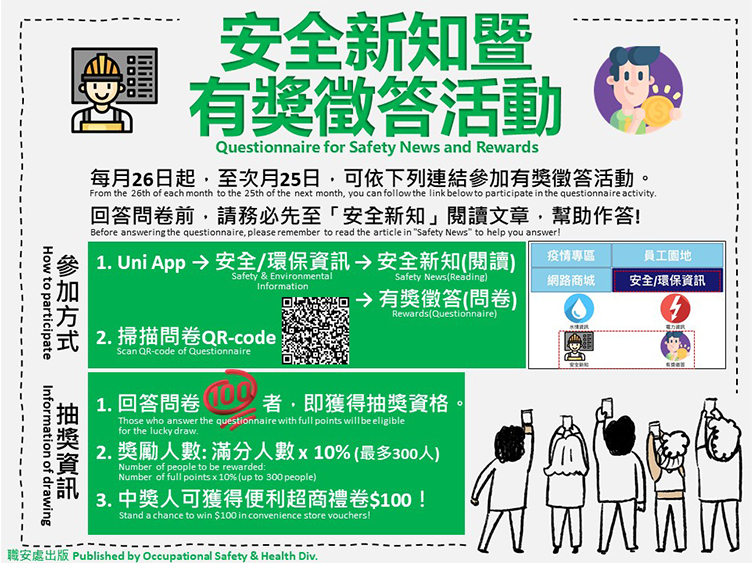

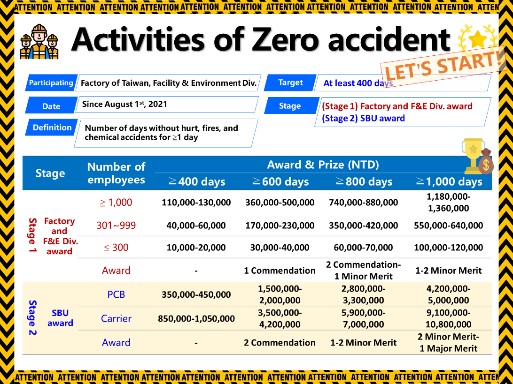

Activity of safety and encouragement

In order to enhance the participation of the employees and to deepen the important concept of occupational safety and health, the mechanism has been set up to encourage employees to participate in the company's safety activities actively. The list of the safety activities in Unimicron is as follows. According to the participants in the activity, it can be divided into competitions of Facilities/offices.

Check/Audit

Besides OSH management of daily check and project check. Unimicron promotes program check and internal auditing system in 2022. The project check including OSH manage, fire facilities, emergency equipment, accident cause improvement and the OSH internal auditing run in year and rating performance basis the audit result, accident and the other activity, it is for the OSH division to regular implement. According to OSH division check and audit result, to assist the plant find out the shortcomings and weakness and make improvement. Attached is the OSH division promote check/audit project in 2022:

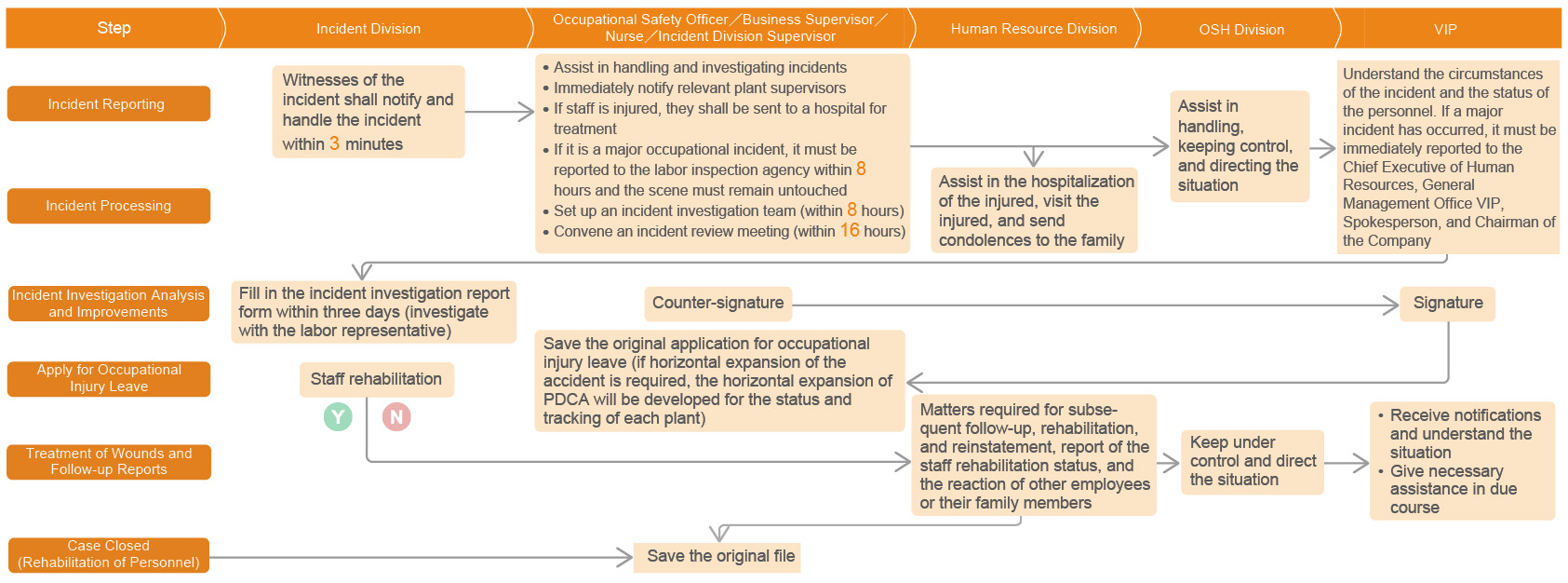

Accident Management

Unimicron has formulated management procedures for occupational safety incidents, there are regulations at all stages from notification, emergency response, investigation, review, prevention of recurrence and parallel deployment, to reduce and prevent the recurrence of similar incidents.

In 2022, Unimicron’s employee disabling frequency rate (F.R.) decreased by 7% compared with 2021, and the employee disabling severity rate (S.R.) increased by 25% compared with 2021. The increase was mainly due to the increase in the severity of accidents and the increase in the number of lost days. According to the analysis, there were 52 cases in which workers in Taiwan Facilities took more than one day off from work due to work-related injuries, among which there were three major occupational accidents. In the review after the incident, it was confirmed that the main cause was the improper installation of facilities and the lack of safety awareness of personnel. Therefore, in strengthening the safety of facility installation, in addition to removing the improperly installed facilities at the incident site, the review was carried out in parallel to see if the same conditions existed in other areas of the factory in order to prevent the occurrence of the same situation. In order to enhance the safety awareness of personnel, in addition to education and training, we have also set up relevant operating regulations, requiring personnel to obtain qualified operating licenses before they can apply for and perform relevant operations. Compared with 2021, the employee disabling frequency rate (F.R.) decreased by 22% and the employee disabling severity rate (S.R.) increased by 36%, with the main types of accidents being 17 cases (33%) of careless walking, 9 cases (17%) of equipment clamping/rolling/crushing injuries, 8 cases (15%) of smashing injuries, and 6 cases (12%) of tool stabbing/cutting injuries.

The total number of workers in the plants in mainland China who took more than one day’s leave due to work-related injuries was 22. Compared with 2021, the disabling severity rate (S.R.) of employees decreased by 9% and the disabling frequency rate (F.R.) of employees increased by 20%. The main types of accidents were 10 cases of careless walking (45%), 4 cases of smashing (18%), and 4 cases of equipment clamping/rolling/crushing injuries (18%). For the overall prevention of injuries, we will continue to promote a culture of safety and active safety protection for all employees every year during Safety Month, and implement a 6-hour occupational safety and health retraining course for injured employees, requiring them to pass a test.

Work Injury

Note 1: Disabling Injuries Frequency Rate (FR) = Number of disabling injuries × 106/Number of hours worked.

Disabling Injuries Severity Rate (SR) = (Number of workdays lost) × 106/Number of hours worked.

The number of work injuries is defined as the number of cases in which a worker could not resume work after an occupational injury for more than one day (inclusive).

The total number of workdays lost is defined as the number of days in which the worker could not resume work after an occupational injury for more than one day (inclusive).

The total number of days lost does not include the calendar days of the day of the injury and the day of resuming work.

Note 2: The definition of high-consequence injury includes fatalities, or does not or is not expected to recover fully to pre-injury health status within 6 months.

Note 3: Disabling Injuries Frequency Rate (FR) and Disabling Severity Rate (SR) of contractors and dispatch were 0 from 2019 to 2022.

In 2022, recordable occupational injuries totaled 74 cases. The OSH of the accidents will be improved and reviewed in order of occurrence based on the severity and frequency of occupational disasters.

2022 The Group’s Recordable Occupational Injury Statistics

Note 1: Injury rate (IR) = Number of recordable work-related injuries/number of hours worked × 200,000.

Note 2: Revise the definition of recordable occupational injuries in 2022. The number of recordable occupational injuries refers to occupational injuries with a loss of more than one day.

Unimicron has established an occupational accident reporting, investigation, and improvement process in accordance with the Occupational Safety and Health Management System Regulations. The accident investigation includes hazard identification and risk assessment of the accidental workflow, as well as improvement measures required by the OSHMS.

OSH Training

Each year we set the annual OSH education and training plans for employees (including contractors). Apart from physical courses, we also provide relevant courses on the e-learning platform, enabling employees to study online at the Unimicron E-College. In addition, to prevent all types of emergencies, each plant and unit shall implement emergency drills for disasters such as fire, chemical disaster, occupational disaster, fire safety, natural disaster (e.g., earthquakes and floods), equipment fires, fire evacuation drills, chemical spillage, work-related injuries, confined space operations of each year, to enhance all staff’s emergency response capability and ensure the stability of operations.

2022 Occupational Safety Training

Contractors’ OSH Training

Emergency Response Drills

2022 Types of Emergency Response Drills

Emergency Response Team (ERT) Drill

From 2021 to the present, Unimicron has been focused on deepening the field commander's response and decision-making capabilities, strengthening the commander's response, decision-making, sand-table deduction, and dispatching capabilities and establishing an Emergency Response Team (ERT) in each plant to strengthen the emergency response capabilities in the field.

- In the emergency response process, when the unit in the abnormal area and the responsible unit cannot complete the rescue right away, the commander must convene and command the emergency response team, issue relevant disaster relief instructions, and evacuate the plant. The plant commander conducts the initiation of the emergency response team and takes evacuation action. If the emergency response team cannot effectively control the disaster condition, while the fire brigade is arriving at the scene, the plant commander directly transfers the authority to an external unit and assist in providing relevant information. By 2022, the number of plant supervisors trained in fire command and response training reached 627 in the plant's self-defense and firefighting team.

- Each plant has established an Emergency Response Team (ERT), to effectively improve the responders’ on-site search, emergency response, fire-fighting equipment suit and Self-Contained Breathing Apparatus (SCBA) wearing, the use of fire hose nozzles, and the response, decision-making and dispatching capabilities. By 2022, there are 374 employees who have completed ERT training.

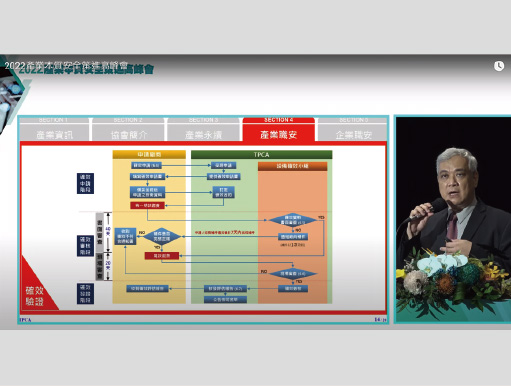

Active Participation in External Engagement and Experience Sharing

In terms of OSH management, besides our strict internal management, Unimicron also actively participates in OSH activities of external, and private organizations, hoping to contribute to the promotion of OSH in the industry. Unimicron is mainly involved in TPCA and the North District Promotion Association of the TOSHMS, and volunteers for the occupational safety counseling organized by the OSH Administration, Ministry of Labor.

Since 2013, Unimicron serves as the convener of the OSH Committee of the TPCA to assist in relevant guidance, as well as discussion and implementation of relevant plans or projects of the PCB industry. In 2022, Unimicron's Senior Advisor continued to serve as Chairperson of TPCA to promote and improve sustainability through experience sharing and exchange.

In 2022, the Company assisted TOSHMS Northern Region Promotion Association to compile an overview of COVID-19 management cases, assisted in project implementation and participated in observation activities. In the same year, the Company continued to serve as the activity implementation officer of TOSHMS North Region Promotion Association and the lecturer of the second education seminar to share the SDGs disclosure practice for sustainable health and safety in the workplace. Through experience sharing and exchange, the Company promoted and enhanced the excellent OSH culture in the industry. This year, we actively participated in the Occupational Safety and Health Poster Contest and submitted a total of 18 entries.

To improve the domestic occupational safety standards and assist the public sector to promote OSH, since 2015, Unimicron has continued to participate in the SME Counseling Volunteer Program of the OSH Administration, Ministry of Labor, to assist the improvement of on-site OSH (including chemical management) and the upgrade of the OSH management systems in small and medium-sized enterprises. In 2022, in cooperation with the Ministry of Labor’s guidance of the SMEs to assist small and medium-sized enterprises to establish occupational safety and health management systems for a total of 4 sessions. By the end of 2022, Unimicron had invested a total of 21 people in the volunteer counseling project and assisted in 93 counseling visits.

2022 Achievements

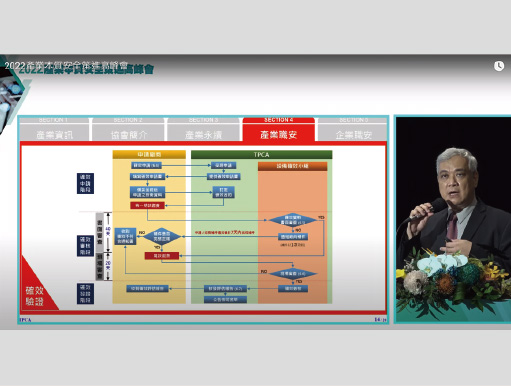

OSH Administration’s Summit on Industry Smart Intrinsic Safety Promotion – Representatives of Unimicron participated in the sharing session

OSH Administration’s Summit on Industry Smart Intrinsic Safety Promotion – Representatives of Unimicron participated in the sharing session

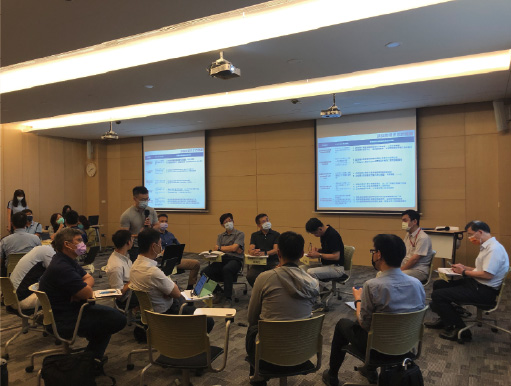

Participation in the TPCA Net Zero Strategy Expert Workshop

Participation in the TPCA Net Zero Strategy Expert Workshop