GHG Emissions

| Topics |

GHG Management |

| Policy |

• Comply with laws, customers and other relevant requirements, and create an environment-friendly and energy-saving working environment |

| Commitment |

• Managers at all levels implement environment/energy/water resources/resource management, and cherish energy and natural resources |

| Division |

• All Divisions/Facility & Environment Division |

| Resources Invested |

• Retirement of inefficient equipment and introduction of energy-efficient facilities |

| Grievance Mechanism |

• There is a hotline/mailbox for whistleblowing, which will be forwarded by each contact person to the responsible unit for confirmation and then respond to the interested party |

| 2022 Targets |

• GHG emission intensity based on revenue<12 (ton/million in revenue) |

| Actions |

• Replace high energy-consuming facilities, use energy-saving equipment, and introduce intelligent control and energy management systems

• Set energy resource management goals and plans, and conduct impact and response assessments in accordance with international trends and laws and regulations |

| 2022 Achievements |

GHG emission intensity based on revenue: 6.71 (ton/million in revenue) |

Note: The base year for greenhouse gas emissions is 2020, and 2025 is set as the target year for carbon peaking. Scope 1 & Scope 2 emissions are used as the reduction targets.

Inventory and Reduction

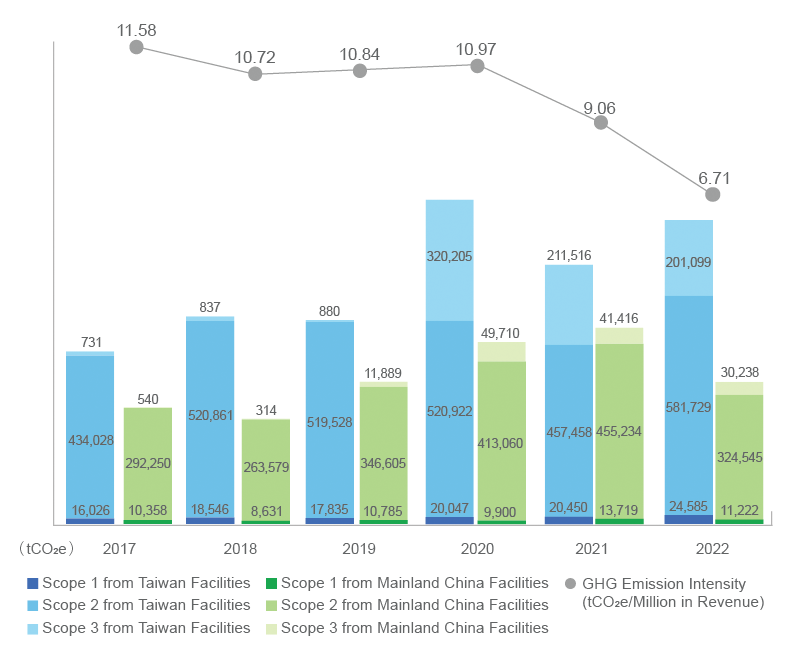

Unimicron follows the ISO 14064-1:2018 greenhouse gas inventory standard to perform inventory operations, and the boundary area includes its factories in Taiwan and China, so as to grasp the overall greenhouse gas emissions situation, and then review and set carbon reduction targets. In addition to monitoring the carbon emission intensity of each factory every year, Unimicron also formulates a three-stage long-term carbon reduction plan based on international trends and government policies. The first phase is from 2021 to 2025, and 2025 is set as the carbon peak year by taking into account the Group's expansion plan. During which we will continue to implement energy-saving improvements at our plants and build energy storage facilities, with the goal of reducing carbon emissions by 8% in 2025 compared to the projected peak. The second phase is from 2026 to 2030, with a target of 30% reduction in carbon emissions in 2030 compared to the projected peak, through the purchase of renewable energy and the installation of green power facilities. The third phase is from 2031 to 2050, with a target of achieving carbon neutrality in 2050, by increasing the purchase of renewable energy in addition to continuing to promote energy conservation improvements. According to statistics, the total emissions of Scope 1 and 2 in 2022 was 942,080 tons of CO2e, a decrease of 0.5% compared with 2021, and a decrease of 2% compared with the base year of 2020. GHG emissions intensity per million revenue decreased by 26% compared to 2021 and 39% compared to the base year 2020, due to improved production efficiency and increased Group turnover, resulting in a reduction in GHG emissions intensity within the Group.

GHG Emissions and Intensity

| Scope |

Region |

Unit |

2017 |

2018 |

2019 |

2020 |

2021 |

2022 |

| Scope 1 |

Taiwan |

Metric Tons of CO2e |

16,026 |

18,546 |

17,835 |

20,047 |

20,450 |

24,585 |

| Mainland China |

10,358 |

8,631 |

10,785 |

9,900 |

13,719 |

11,222 |

| Subtotal |

26,384 |

27,177 |

28,620 |

29,947 |

34,169 |

35,807 |

| Scope 2 |

Taiwan |

434,028 |

520,861 |

519,528 |

520,922 |

457,458 |

581,729 |

| Mainland China |

292,250 |

263,579 |

346,605 |

413,060 |

455,234 |

324,545 |

| Subtotal |

726,278 |

784,440 |

866,133 |

933,982 |

912,692 |

906,274 |

| Scope 1 & Scope 2 |

Taiwan |

450,054 |

539,406 |

537,363 |

540,969 |

477,907 |

606,313 |

| Mainland China |

302,608 |

272,210 |

357,390 |

422,960 |

468,954 |

335,767 |

| Subtotal |

752,662 |

811,616 |

894,753 |

963,929 |

946,861 |

942,080 |

| Scope 3 |

Taiwan |

731 |

837 |

880 |

320,205 |

211,516 |

201,099 |

| Mainland China |

540 |

314 |

11,889 |

49,710 |

41,416 |

30,238 |

| Subtotal |

1,271 |

1,151 |

12,769 |

369,915 |

252,932 |

231,337 |

| Scope 1 & Scope 2 |

Taiwan and Mainland China |

Metric Tons of CO2e/Million in Revenue |

11.58 |

10.72 |

10.84 |

10.97 |

9.06 |

6.71 |

Note 1: The data of Taiwan Facilities for 2017~2021 does not include Chungyuan Plant, Chung Hsing Plant, Yangmei Plant and Shanying II Plant in Taiwan. The data for 2022 does not include Chungyuan Plant, Chung Hsing Plant and Nanshan Plant.

Note 2: Scope 2 is mainly the use of electricity, and the emission factors are 0.509, 0.58, and 0.581 kg of CO2e/kWh for Taiwan, Eastern China, and Central China in 2022, and 0.5271 kg of CO2e/kWh for Southern China in 2021. For other years, please refer to the Sustainability Report.

Note 3: The base year for carbon emissions is 2020 for the Group's carbon emissions management.

Note 4: GWP value of AR5 is used in Taiwan and Unimicron (Shenzhen), the GWP value of AR6 is used in QunHong Technology Inc., Unimicron-FPC (Kunshan), Unimicron (Huangshi), Unimicron (Suzhou), and Unimicron (Kunshan).

Participation in Carbon Trading

Shenzhen City in Mainland China took the lead in launching carbon emissions trading in June 2013. For companies included in the key energy consumption statistics (monthly emissions> 10,000 tons of carbon emissions, Unimicron (Shenzhen)’s has an average of 15,000 tons/month in 10-12 years) and must conduct compulsory carbon emissions trading (i.e., emission control units). Therefore, Unimicron (Shenzhen) began to join the Shenzhen carbon trading mechanism in 2014. As of 2021, the cumulative carbon emissions were approximately 901,600 tons. Based on industrial value-added, retrospectively, they could get quota in 2021 was about 73,200 tons, and the total cumulative quota was about 1,037,500 tons from 2013 to 2021. After offset, there is still a balance of 135,800 tons, which is temporarily retained without trading. Unimicron (Shenzhen)’s annual carbon emissions have exceeded the carbon emission quotas in recent years, and the remaining carbon emission quotas in the future will be used to offset Unimicron (Shenzhen)’s annual carbon emissions. The 2022 carbon trading mechanism would be implemented in Aug. 2023.