Procurement Risk Management

strengthen the sustainability risk management of the supply chain, Unimicron gradually strengthens the sustainability performance of the supply chain, especially through four steps to review and improve the sustainability risks faced by the supply chain.

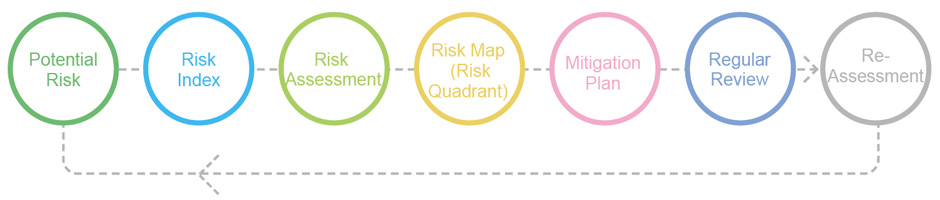

We integrate supply chain risk management into daily procurement operations and construct a Procurement Risk Management Procedure under the supply chain risk management framework. Using the PDCA cycle process, we continuously review the risk status and compile the risk index through the results of quantitative risk analysis. At the same time, the risk heat map is drawn, and the risk occurrence frequency and the degree of impact are used as the assessment basis to formulate the periodic review of the mitigation plan and to implement control of the supply chain’s sustainability risk.

Finally, we communicate and cooperate with suppliers, and through the establishment of mitigation plans, we can gradually reduce the risks faced by supply chain by targeting any high-risk factors that may cause continuous business interruptions, such as single supplier, regional policy changes, and insufficient production capacity, through introducing alternative suppliers or conducting second-supplier or second-origin certification programs according to their supplier attributes.

Procurement Risk Management Process

Procurement Risk Assessment Factors

| Risk Type |

Risk Factor (Tier 1) |

Risk Factor (Tier 2) |

| Internal Risk |

Purchasing Risk |

Integrity Requirements |

| External Risk |

Regulatory Risk |

- Supplier CSR Risk

- Supplier Infringement

- Hazardous Substances Risk

|

| Supply Chain Disruption |

- Business Continuity Risk

- Cost Risk

- Supplier Conflict Minerals Management Risk

- Financial Risk

|

- Supply Disruption

- Raw Material Price

- Smelting Plant RMAP Conformity Management

- Financial Data Monitoring

|

Supplier Sustainability Audit and Advocacy

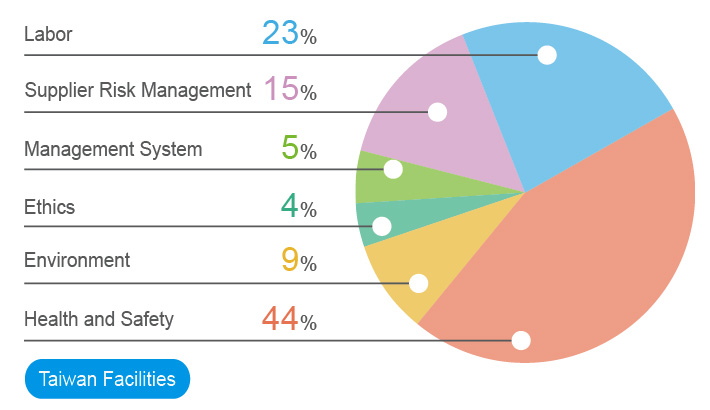

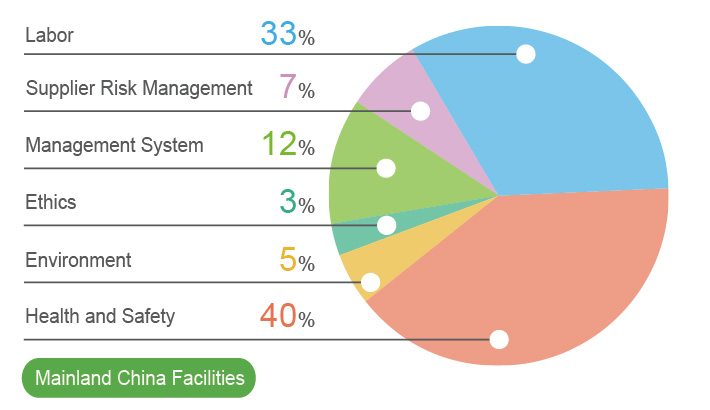

Unimicron has been conducting on-site audits of suppliers since 2011 and has been increasing the number of suppliers audited year by year. In 2022, Unimicron conducted 44 on-site audits of key suppliers in Taiwan and China (the audits were conducted by Unimicron and its subsidiaries), and the results of the on-site audits showed that although there were still deficiencies, no suppliers were classified as high-risk. The main audited deficiencies of suppliers in Taiwan and China were in the aspects of labor, health and safety and supplier risk management.

Unimicron requires audited suppliers to complete or propose improvement plans within the improvement deadline, and by the end of 2022, the suppliers’ deficiency cure rate was 45% in Taiwan and 100% in China. For suppliers who have not completed the improvement or proposed improvement plans, Unimicron will continue to ask suppliers to complete the improvement and uphold the spirit of coexistence and co-prosperity, cooperate with suppliers to promote ESG works, and jointly move towards the goal of sustainable development.

Supplier Sustainability Audit Process

01

Suppliers Self-Evaluate and Provide Written Supporting Information

02

Unimicron Conducts a Document Review

03

Unimicron Conducts on-Site Audit

04

Suppliers Make Improvements Based on Audit Results

05

Unimicron Verifies Improvement Results and Closes the Case

Aspects of Supplier Audit

Labor , Environment, Management System, Health and Safety, Ethics, Supply Chain Risk Management

Supplier Sustainability Audit – On-Site Audit

(Unit: times)

| Year |

2019 |

2020 |

2021 |

2022 |

| Taiwan Facilities |

15 |

15 |

6 |

6 |

| Mainland China Facilities |

34 |

36 |

37 |

38 |

| Total |

49 |

51 |

43 |

44 |

2022 Supplier Audit Violations

Findings and Improvement Actions of 2022 Supplier Audit in Taiwan Facilities

| Categories |

Item |

Main Findings |

Improvement Actions |

| Labor |

- Working hours

- Compensation and benefits

- Non-discrimination

|

- Lack of physiological leave and paternity leave

- Deducting salary as a means of punishment

- Items on the interview resume that involve discrimination

|

- Add family care leave, paternity leave, physiological leave, etc. to the leave list as required by law

- Amend the penalty for deducting salary

- Revise the item on the resume that involves discrimination

|

| Health and Safety |

- Occupational safety

- Emergency Preparedness

- Occupational injuries and diseases

- Sanitation and Accommodation

|

- Insufficient OSH staff and emergency personnel

- The risk of Fire-fighting facilities being blocked

- The contents of the first aid kit have expired

- No water quality inspection report and regular inspection records

|

- Hire more necessary OSH personnel (including emergency personnel)

- Set up a checklist and clear the channel

- Renew the form for “Effective date”

- Inspection regularly

|

| Management System |

- Development goals

- Training

|

- No annual organizational goals and tracking performance

- No RBA-related training records

|

- Setting annual organizational goals and tracking performance

- RBA training on a regular basis

|

| Raw Material Supply Risk Management |

- Supplier RBA Code of Conduct compliance and its supply chain-related communication

|

- The RBA Code of Conduct is not included in the Supply Chain Management Procedures

|

- Suppliers should establish Supplier Management Procedures that require their supply chain to commit to and sign the RBA Code of Conduct

|

Supplier Communication Platform Shares Sustainable Information to Drive Supply Chain Sustainability

Unimicron follows international standards and regulations such as the RBA Code of Conduct, ISO 14001, ISO 45001, and QC 080000. We have also established comprehensive supplier management regulations based on the environment, human rights, safety, health, and ethical principles outlined in the above international standards to promote CSR. We launch campaigns on quality/green products, OSH, information safety, and sustainable management, and communicate with suppliers to create a win-win partnership. Since the COVID-19 pandemic has not yet subsided, the annual suppliers' meeting in Taiwan had been changed to an online advocacy through the suppliers' platform, and it was held in the form of supplier commitment letters and emails for factories in China. All suppliers who have business dealings with Unimicron are the subjects of the advocacy and the advocacy had completed 100%

Supplier Propaganda Theme of 2022 Supply Chain Platform

- Introduction of ESG Supply Chain Management

- RBA Code of Conduct and Sustainability Audit

- Supplier Information Security

- Occupational Safety and Health

- Energy Resources

- Hazardous Substances Free (HSF) of Raw Materials