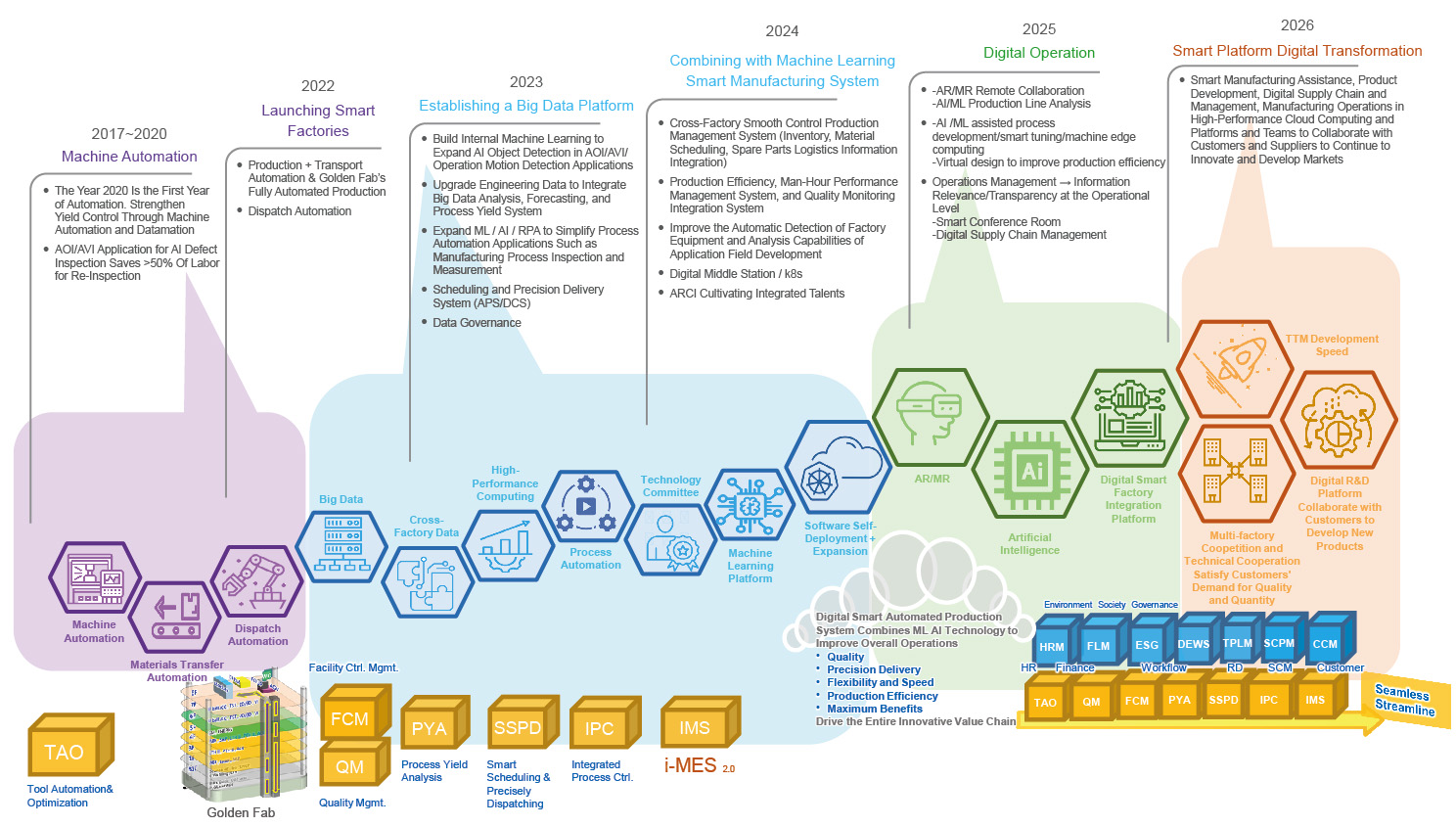

Smart Manufacturing Strategy and Promotion Process

With the speed of disruptive technological advances such as Industry 4.0 and AIOT, the concept of smart manufacturing is being put into practice, not only in the manufacturing industry but also in different industries. As a leading manufacturer in the PCB industry, while facing the challenges of smart manufacturing trends, Unimicron is looking forward to grasping the opportunity of ICT technology advancement to improve the operational capabilities of the speed, quality, cost, and technology of our factories, and to build a manufacturing eco-service system to provide customers with amazing value.

Exploration period – Automation and Internet of Equipment

In 2017, Unimicron participated in the establishment of the PCB Smart Manufacturing (A-Team), a government-supported group of software and hardware companies and PCB manufacturing companies, to introduce standard communication protocols and common platforms, and develop a vertically integrated solution platform by combining software and hardware companies, academic research teams, and research institutions, providing PCB manufacturers with suggestions to meet the smart manufacturing planning. In 2020, we established the Smart Manufacturing Promotion Organization based on the smart transformation team members who participated in the PCB Smart Manufacturing (A-Team). Starting from the internet of machines to intelligent application tool projects, by improving the production process to save manpower and enhancing quality analysis capability, we are entering Unimicron’s first year of smart manufacturing.

Infrastructure construction period - Smart Manufacturing Golden Fab Construction and Big Data Platform

In 2021, we started to expand our AI image technology research team and develop our own AI defect detection technology, which were introduced into AOI/AVI inspection equipment and other inspection equipment, to successfully reduce the number of re-inspection workers by >50%. At the same time, we expanded the level of technology to each factory, and in 2022, we completed the construction of AI models for 117 machines in 7 factories and put them into mass production. We completed the development of 108 intelligent solutions in accordance with the smart development blueprint and expand them to 18 factories. In 2022, after achieving the stage goal of AI saving manpower and efficiency, the intelligent manufacturing task force started the next stage of AI application. Extending from self-developed AI image technology, the application field is expanded to work safety and no-code AI platform, providing factories, providing rapid and independent deployment in factories, and moving forward for the road of AI for all.

As the number of factories continues to expand, in response to the demand for cross-factory collaboration services and big data applications, we have initiated hardware upgrades, MES, information security, data governance, and other basic engineering optimizations to ensure the stability, efficiency, and security (information security) of the maintenance system. At the same time, we also see the benefits of data normalization and data sharing, such as the integration of multiple data through foundation construction and breaking the limitation of " information island" to provide engineers with a data analysis service platform to help quickly analyze the causes of abnormalities, which can be completed in 5 minutes, solving the troubles and limitations of engineers' analysis and reducing the impact on production efficiency and quality.

With Unimicron’s announced vision of improving the operational capabilities of the speed, quality, cost, and technology of our factories and providing amazing value to our customers, Unimicron introduced the SECS communication protocol infrastructure and completed two demonstration factories in the Taoyuan area equipped with production machines, material transportation, production scheduling, and dispatch automation, and will enter mass production in 2022. Based on the Golden Fab, we will continue to introduce and update various smart and innovative solutions to realize energy-saving and environmentally friendly smart manufacturing factories.