Products and Quality

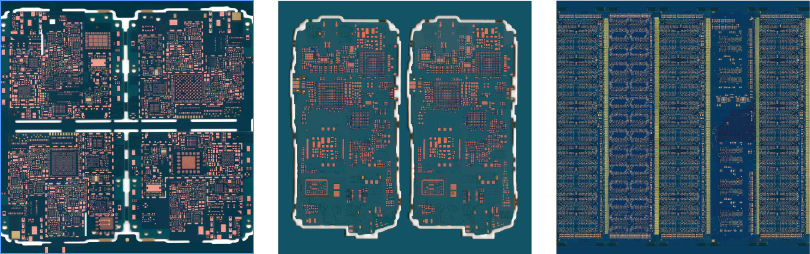

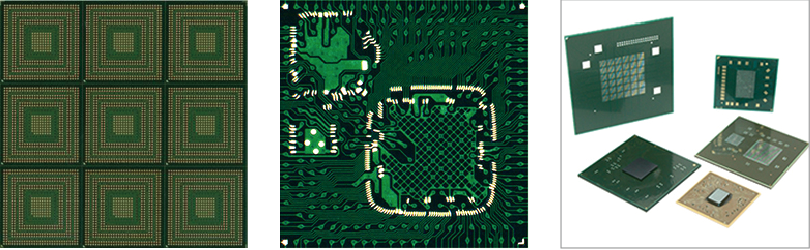

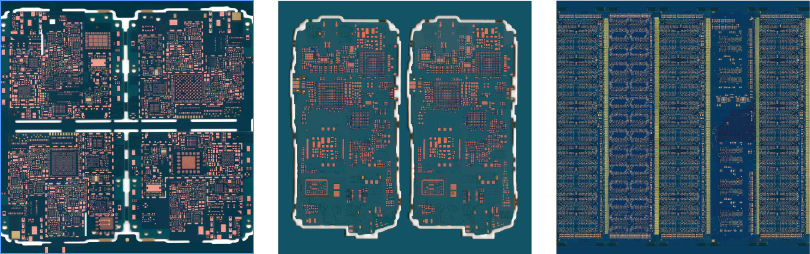

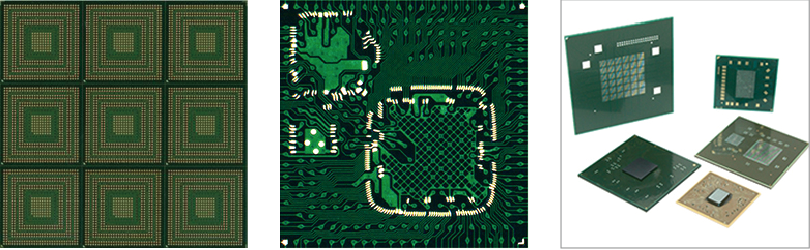

Unimicron’s main business items are engaged in the development, manufacturing, processing and sales of Printed Circuit Boards (PCB), High-Density Interconnect Printed Circuit Boards (HDI PCB), Flexible Printed Circuits (FPC), rigid-flex PCB and Carrier. The main products are the manufacturing and processing of PCBs (including Carriers), etc.

Substrates are used for assembling electronic components the main purpose is to connect each electronic component to form an electric circuit on the PCB so that it can function and relay transmissions. The applications of PCBs are wide-ranging including but not limited to computers and related industries, communications, consumer electronics, automotive parts, aerospace, precision instruments, and industrial products. Since PCBs do not have uniform specifications that can be roughly distinguished by softness and the number of layers. They can be classified by softness, i.e., flexible and rigid-flex boards, and by the number of layers, i.e., single-layer boards, double-layer boards, and multi-layer boards.

Their main function is to hold the IC chip and connect the signal between the chip and the PCB through the internal circuits of the IC substrate. Their main purpose is to protect the electric circuit, set the wires in place, and dissipate heat. Depending on the packaging technology, IC substrates can be divided into Ball Grid Array (BGA), Chip Scale Package (CSP), and Flip Chip (FC).

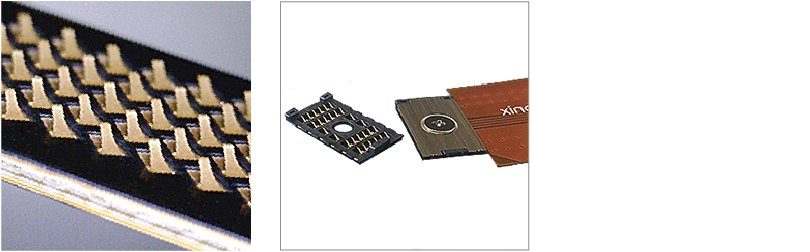

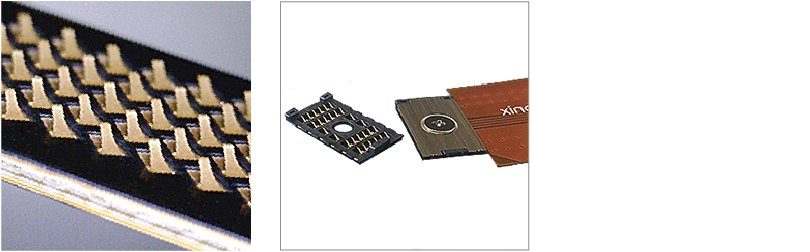

Unimicron has obtained a patent from US Neoconix to manufacture PCBeam™. It is high-speed (>40Gbps), ultra-thin, and easily customizable, following the trends of modern electronic products. It can be used in fields such as Board-to-Board, Board to Flex, Board-to-Device (Socket), and its markets include industries such as consumer electronics, healthcare, industrial use, and high-speed communications. The PCBeam™ team provides a range of customized solutions to customers, breaking the current restrictions on connector designs and making our products more competitive.

Customer Orientation / Dedication Towards Quality / Continuous Breakthrough

- Commitment, Support and Leadership of Senior Managers

- Customer Satisfaction Management

- Company-wide Participation in Continuous Improvement

- Application and Management of Process Flow and Quality Information

- Employees’ Education, Training and Growth

- Construction of the Quality Management System

- Adopt Best Practices

- Adopt Refined Policy Management to Move towards Becoming a World-Class Company

Quality Management

Unimicron is committed to providing high-quality and reasonable-priced products and competitive delivery and services. It has a quality policy of "customer-oriented, quality first and continuous breakthrough," integrating high-quality culture into the core of the Company to meet customer expectations and achieve the vision of "a world-class high-tech Company with high value-added, high quality, high productivity, and emphasis on innovation and services."

Total Quality Management (TQM) is deemed an important part of Unimicron’s operations. We use customer-oriented management to promote team cooperation and cross-departmental management. Since 1996, the Total Quality Management Committee has been established to implement total quality management, with four subcommittees under it, including the Lean/6σ, the Quality & Standard/Knowledge Management, the Education Training, and the Quality Control Circle. The Knowledge Management subcommittee will introduce new systems and intelligent development to improve quality management.

Total Quality Management (TQM) Committee

Secretary Division

TQM Committee

Director General

Lean Six Sigma Subcommittee (Lean/6σ)

Formulate the Lean/Six Sigma Action Plan and various quality indices, and track and the status. Assist plants/units in selecting projects and audit GB/BB/MBB certifications

Quality & Standard/Knowledge Management Subcommittee (Q&S/KM)

Implement the operation of the quality system to achieve continuous quality improvement and take charge of the operation of the knowledge management system

Education Training Subcommittee (ET)

Cultivate correct TQM concepts for use at work and in life. Establish the education and training system by level and function to train staff, management, and internal instructors

Quality Control Circle Subcommittee (QCC)

Revise and promote the Unimicron’s entire quality assurance system and improvement proposals, events and regulations. Track, document and archive training effectiveness. Combine the training assessment results with the employee promotion system for a sound Human Resourcesystem for the Company

TQM Committee’s Functions

- Customer-Oriented Management

- Policy Management and Daily Management

- Continuous Improvement

- Making Quality Products Is Everyone’s Responsibility

- Promote Team Cooperation

- Emphasize “Prevention Is More Important Than Inspection” and “Do It Right the First Time”

- Take Care of Both Processes and Results

- Promote Cross-Departmental Management

To expand the application range of our products, we are committed to the establishment and implementation of the ISO 9001 Quality management system, the IATF 16949 Automotive Quality Management System and the QC 080000 Hazardous Substance Process Management System, pursue continuous quality improvement to enhance competitiveness, and drive all employees to improve their work performance, achieving the goal of overall quality improvement.

Unimicron strives to be a world-class supplier of electronic parts and materials. Our quality policy aims to be customer-oriented, quality-oriented, and continuous breakthrough, and to create a dynamic environment where employees enjoy working. With this philosophy, Unimicron has been promoting company-wide quality control circle related activities since 1996, so that all employees can work together as a team to increase cohesion, brainstorm and learn from each other, improve employees' problem-solving capability, move towards diversified development, and grow and thrive together with the Company.

2022 Honored of Golden Tower Award of TCIA

■ Award: Perfection Group Self-Improvement (Quality) Category-Golden Tower

Project: Great Leap Forward in the Yield Rate of New Generation Products - Improving the Appearance Yield Rate of ABF Carrier Boards

The award-winning team, Xinyue Circle, is from the S2 factory of Unimicron’s Carrier Board Division. The factory mainly produces advanced IC carrier boards to meet the demand of new-generation chips. In recent years, with the rise of cloud network applications, a large number of network data centers and workstations have been built, leading to an increase in demand for servers and switches, and IC carriers are widely used in high computing performance products, which have long been inseparable from everyone's life. With the concept of continuous breakthrough and excellence, we have continuously used PDCA improvement to achieve better management and quality and become the world's largest IC carrier board supplier.

The theme of this project is "New Generation Product Yield Improvement - Improving ABF carrier board appearance yield". The project was to design through experiments to find the best solution, introduce new process technology, modify machines, self-make production jigs, design new carriers and establish a prediction system through big data analysis, to improve production efficiency and overcome capacity bottleneck. We successfully solved the problem of quality and yield within one year and shipped the products to achieve a win-win situation for both customers and the Company. Looking into the future, Unimicron is committed to integrating intelligent production into the industry by expanding our production bases around the world and centering on Taiwan. Adhering to the customer-oriented management method, we will continue to promote QCC quality control circle activities and insist on total quality management culture. With the participation of all employees and taking into account the quality of both results and processes, we will continue to develop our technology, leap into the world, and pursue excellence to continue to be a leading company in the industry.

■ Award: Perfection Group Indirect Department Category-Golden Tower

■ Project: Increasing Water Recovery in the SY plant, towards the Goal of Water Sustainability

The award-winning team, the Environmental Circle, comes from the Facility & Environment Div. of Unimicron, and integrates the resources of the plant's Energy Conservation and Carbon Reduction Subcommittee, Equipment Div., supplier and TQM, with the topic of "Increasing water recovery in the SY plant area, towards the goal of water sustainability", forward sustainability efforts.

Because of the limitation of industrial characteristics, Unimicron must rely on stable water resources. Therefore, the stability of water quality and quantity is one of the most important keys to the company's continuous operations. In Taiwan, there is a significant difference in rainfall during wet and dry seasons. Moreover, Taiwan had many phenomena of extreme weather and hydrological extremes in recent years. In order to ensure the factories operation and avoid an immediate crisis of water shortage which is due to a lack of water resources, the factory must improve the risk tolerance of water shortage. Therefore, tracking the storage of reservoirs in various regions and monitoring the water management status of each factory is a daily routine.

To reduce the consumption of water resources, we continuously increase water recovery systems that reclaim low-pollution water generated from various processes, to replace industrial production water. Continue to promote effective management, environmental-friendly and energy-efficient ways to let every drop of water resources that are from the front end to the final discharge move toward the sustainable goal of zero waste of water. Adhering to the 3P principles of Planet, People, and Performance, we continue to improve water-saving technologies to increase water efficiency and practice our commitment to environmental sustainability.

■ Award: Special Group of ESG Sustainability Best Innovation Award & Golden Tower

■ Project: Improve the Job Retention Rate of Dun-Pin High School Students after Leaving School, to Fulfill Corporate Social Responsibilities

The award-winning team, Xin Xiang Quan, came from the Administrative Services Department of Unimicron’s Shanying Plant, integrating the resources of the Human Resources Division, Plant Technology Department, and TQM within the plant, while inviting the Qingxiang Youth Care Association and OK Stores for cross-industry cooperation. With the theme of "Enhancing the job retention rate of Dunpin High School students after they leave school to fulfill the corporate social responsibility", we will do our part for social responsibility together.

Unimicron’s Administrative Service Department and the Taipei Prison of the Agency of Corrections, Ministry of Justice have formed a relationship through cooperation on the "work release program." In 2022, Xin Xiang Quan took root further down, combining Unimicron’s ESG policy- a better society in social responsibility with the Agency of Corrections, Ministry of Justice (Dunpin High School), hoping that through the cooperation, we can start a social reintegration program for students and nurture their work ethics and future development.

The project is full of challenges and hardships, and Xin Xiang Quan hopes to strengthen the function of youth counseling and bridging employment through the close connection of all parties, so that juvenile delinquency can have a stable job and normal work and rest after leaving school, and adapt to social life. In the process of activities, QCC spirit and methods are also introduced to instill students' quality concepts in experience and technology during the project activities, so as to increase students' self-confidence in job seeking and employment after leaving school, and to stabilize their economic income and turn their lives around to regain hope.

Due to the inadequate establishment and lack of resources, juvenile reformatory schools have been restructured into juvenile correctional schools. With the successful experience of cooperation between Dun-Pin High School and Unimicron, we have expanded the program to four major correctional schools in Taiwan. Young people are the seeds of social progress and national prosperity. Unimicron hopes to join hands with other major enterprises to support, stabilize, warm and help juvenile delinquency, and create social harmony values together.