Innovative Technology R&D

| Topics |

Chemical Safety |

| Policy |

- Formulate correct R&D strategies, effectively integrate factory resources, and exert synergy

- Protect research and development results and defend the Company's intellectual property rights

|

| Commitment |

- Develop new products, providing the basis for sustainable management of the Company

- Protect our own intellectual property rights and respect the intellectual property rights of others

|

| Division |

- R&D Div. and New Business Development Div.

- Intellectual Right Div.

|

| Resources Invested |

- Invest funds in research and development and invest in new equipment to cultivate research and development talents

- Purchase patent search engine and intellectual property related training courses

|

| Grievance Mechanism |

- Whistleblower hotline and mailbox

|

| 2022 Targets |

- ETS fine line development: L/S = 5/5 um AOI yield > 85%

- Fine bump pitch development: POC for 80um pitch w/via bump

- Hybrid substrate development: Thin film RDL bonded organic substrates 2/2um L/S

- Mass production ratio of 5G technology: 30%

- Number of patent applications: 100

|

| Actions |

- Implement performance management according to BP, review progress weekly, and review results monthly

- Quarterly review of the patent situation

|

| 2022 Achievements |

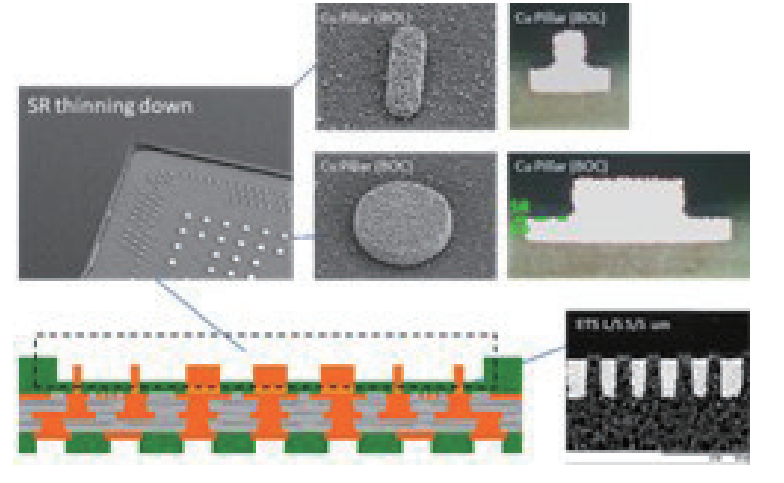

- ETS fine line development: L/S = 5/5 um AOI yield > 86.5% Cooperate with suppliers to develop Cu pillar and solder mask thinning process

- Fine bump pitch development: POC for 80um pitch w/via bump. Evaluation and selection Via Bump production technology

- Hybrid substrate development: Thin film RDL bonded organic substrates 2/2um L/S

- Mass production ratio of 5G technology: 30%

- Number of patent applications: 170

|

continuously enhance our corporate value, we actively refer to and develop the technical blueprint of the international industry to meet the needs of various future products. Through the three strategies of the patent portfolio, technological development and technological cooperation, we actively invest in environmental protection and low-cost manufacturing processes and establish an industry centered on technological innovation and intellectual autonomy, to open up new business opportunities through innovation.

Breakthrough Innovation

- Establishing Technology and Product Innovation Platforms

- Resources and Teamwork Integration

- Strategic Benchmarking Learning with Partners

- Refine System Processes and Management

Discover New Business Opportunities

- Gain Insight Into Industry Development Opportunities

- Mastering Technology Market

- Rapid Response to Market and Customer Needs

Enhance Corporate Value

- Environmental Protection and Sustainability

- Fulfillment of Corporate Social Responsibility

Patent Portfolio Strategies

We have formulated three major patent management strategies “Innovative Technology Protection, Patent Strategy Development, Patent Map Compilation” to strengthen Unimicron's position as a leader in the market and plan a Patent Portfolio to enhance Unimicron's value and competitiveness. Actively developing Heterogeneous Integration technology and applying for multiple patents to protect our technology assets.

To further capture R&D achievements with customers and suppliers, and to hold patents, Unimicron protects our R&D achievements through internal patent application system tools, and leverages our Portfolio to enhance our value and competitiveness, to solidify our leading position in the market in the era of the knowledge economy.

Innovative Technology Protection

- Application for R&D Innovation Retention

- Share the Results of Industry-Academia Cooperation with Partners

- Jointly Hold Patented Technology with Partner

Patent Strategy Development

- Advanced Technology Development

- Patent Strategy Research and Layout

- Patent Risk Assessment and Avoidance

Patent Map Compilation

- Patent Classification Control Mechanism

- Periodic Review of Patent Assets

- License Utility Expansion

Patent Achievements

| Region |

Type |

2019 |

2020 |

2021 |

2022 |

| Taiwan |

Patent Applications |

34 |

48 |

62 |

56 |

| Patent Granted |

32 |

34 |

57 |

61 |

| America |

Patent Applications |

39 |

41 |

50 |

55 |

| Patent Granted |

21 |

31 |

33 |

38 |

| Mainland China |

Patent Applications |

30 |

45 |

50 |

59 |

| Patent Granted |

19 |

24 |

45 |

40 |

| Others |

Patent Applications |

0 |

2 |

0 |

0 |

| Patent Granted |

7 |

8 |

3 |

0 |

Technological Development

With Unimicron’s strategy to stay rooted in Taiwan and expand globally, we have set up R&D centers in Taoyuan (including Shanying II Plant and Yangmei Plan) and Hsinchu, with different R&D strategies that are focused on developing technologies to satisfy customers’ needs and developing innovative technologies for the next three to five years. In addition to introducing advanced equipment and recruiting R&D talents of the industry, Unimicron has also invested heavily in research and development. Currently, the annual investment in research and development is about 1% of the annual revenue. The R&D expenditures invested in the past years have grown gradually in order to maintain and strengthen our competitiveness and customer satisfaction by creating proprietary, leading-edge, and stable technologies. At the same time, we are actively investing in environmental protection and advanced manufacturing processes to establish an industry with technological innovation and intellectual autonomy.

R&D Expenses

| Year |

2019 |

2020 |

2021 |

2022 |

| R&D Expenses (NTD in 100 million) |

6.48 |

9.79 |

11.06 |

15.84 |

| Ratio (%) |

0.8 |

1.1 |

1.1 |

1.1 |

1: The scope of patent fee includes Carrier SBU, PCB SBU and New Business Development (NBD) Team.

2: The increase in the 2022 patent fee mainly was invested in new facilities and expansion of the R&D organization. Therefore, the 2022 patent fee is higher than 2021.

Technological Development

In response to future industry trends, Unimicron will continue to invest in research and development, and cultivate high-end product technology platforms, such as 5G high-frequency high-speed PCB products, ultra-small distance pitch LED module development, Cool PCB (High Thermal Conductive) module development, Nick-Free (NF) new technology development, and high-end Photovia PCB technology development.

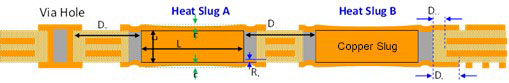

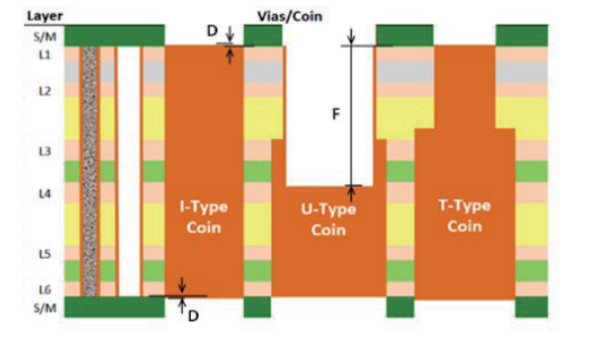

At this stage, we are facing the global commercialization of 5G mobile communications. We are focusing on four major areas in research and development, which are smart phone/NB HDIs; antenna-in-package high-frequency PCBs, radar boards, and antenna arrays; optoelectronic telecommunication boards for optical modules; and PCBs with high layer count and high-speed PCBs for various servers, network switches, and routers. The heart of technological development for PCBs includes the mSAP (L/S=18/22 µm) fine line process, embedded Cu inlay technology with quick heat dissipation, coaxial via-low energy loss technology, the mechanical drilling and copper plating technology for boards with a thickness of 5.4mm and a high aspect ratio (32:1).

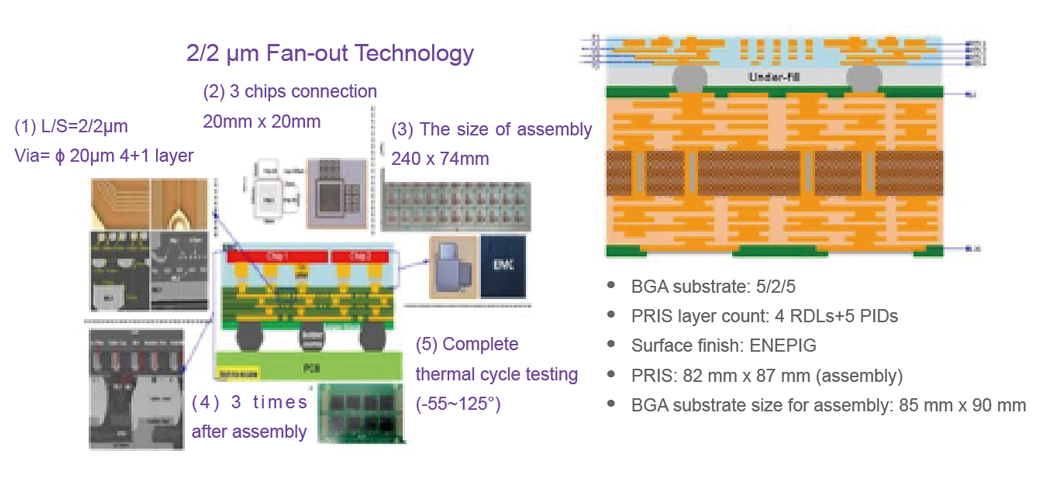

Relying on its expertise and experience in large panel manufacturing of PCBs/IC Carriers, Unimicron is equipped with the existing Coreless technology, based on the platform of innovative multilayer film wiring technology, to integrate materials and equipment manufacturers in the semiconductor and panel industries to form a research and development alliance. We develop the advanced packaging technology of Panel-level Fan-Out (PFO) with RDL first (Die last) and fine line process (2μm/2μm line width/line spacing) to break industrial problems and technical challenges of Fan-Out Panel Level Package (FOPLP), driving the development of the overall industrial chain. In addition, in response to the future trend of high-density multi-functional chip systemization, based on the original platform of ultra-fine circuit technology, we adopted Multichip Heterogeneous Integration Packaging Technology, and the packaging size will be expanded from 20mm x 20mm to 55mm x 55mm.

Regarding the technology development of Embedded Trace Substrate (ETS), we have adopted new equipment and liquid medicines research in the redevelopment plan of the S1 Plant and strengthened the freight handling and FM control to improve the L/S 6/8um to the customer's certification level. We are also working with VIP customers to develop the L/S 5/5um platform in advance, with a variety of dry film and exposure machines, as well as the testing of surface treatment chemicals to lay the foundation for the next generation of mobile communication.

| Item |

Comparison with the Previous Year |

| Fine Line Process Technology |

completed the composite substrate technology platform (RDL+HDI, RDL+BGA) and reliability verification as well as the multi-chip heterogeneous integration package on composite substrates, with a package size of 20mm x 20mm to 50mm x 50mm, 5 redistribution layers, and a minimum line width of 2µm. |

| Technological Development of Embedded Trace Substrate (ETS) Fine Line |

response to the need for high-density packaging and interconnection of chip nodes below 2 nm, we developed a Cu pillar and solder-mask thinning process on the L/S 5/5 um platform in cooperation with our supplier, making a Cu Pillar with a height of about 4~10 um on the bump pad exposed to the solder mask layer. |

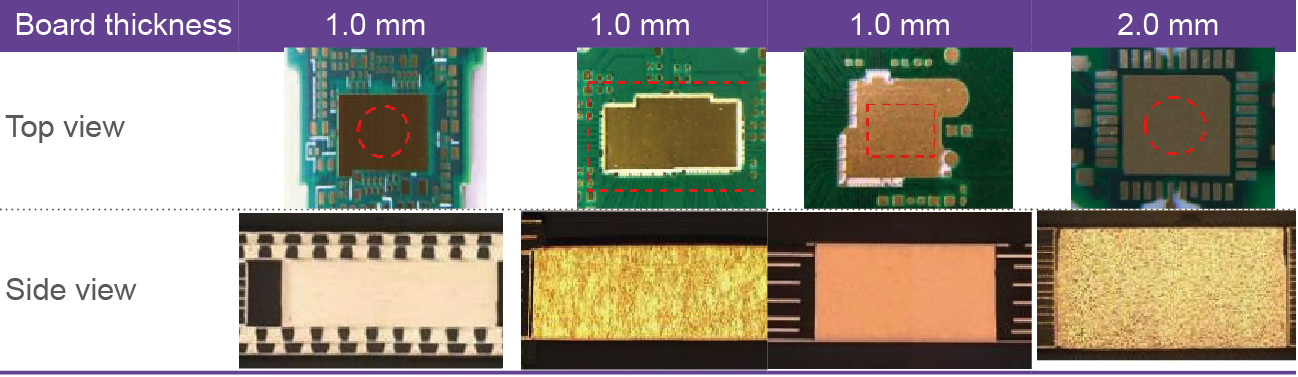

| Technological Development of Hybrid CU Inlay |

Coin 0.2~2mm, Dimension< 6x15mm embedded technology development |

Single-shape Cu Inlay

Embedded Heat Slug

Hybrid Cu Inlay

|

Technological development of Embedded Trace Substrate (ETS) fine line (Cu Pillar and Thinning Anti-Solder)

|

|

|

|

Technological Cooperation

Unimicron recognizes that cooperation with the value chain plays is the key to driving toward sustainable innovation. In addition to working with international manufacturers to develop next-generation high-end IC Carriers and interacting with customers, the Company also knows customer needs for technology and next-generation products, and keeps tabs on the blueprint for customers' future products. We strengthen cross-sector cooperation among domestic industries, create industry and products, strengthen research and development relationships between industry, academia, and research institutes, drive the industry to set new specifications, and promote industrial optimization. We will continue to meet customer expectations with the best quality and service model, lead the overall value chain forward, and create more value.

| Strengthen Cross-Sector Partnerships |

AIoT and 5G drive diverse industrial applications, requiring higher heterogeneous integration technologies to meet performance demands. Now, semiconductor manufacturers around the world are accelerating the development of heterogenous chip integration processes. In 2025, the world will enter the 2nm advanced wafer node and the substrate interconnection pitch will be≦40µm, which will require more System-in-Package(SiP), small chips, and heterogeneous integrated package. Unimicron can provide a heterogeneous integration platform that supports advanced substrates for IC carriers. In 2021, we began the development of a multi-chip heterogeneous integration package technology platform. The size of the package will gradually expand from the current 20mm x 20mm to 55mm x 55mm after 2022. |

| Develop Industry and Products |

The COVID-19 pandemic in the first half of 2020 and the border controls adopted by various countries had a strong impact on the global supply chain. Also, in response to the risks posed by climate change, net-zero emission targets have been established in countries around the world, which has led to major brands in the IT and communications industry demanding their supply chain to comply with RE100, which asks for 100% green energy use. The carbon rights and taxes that will follow these initiatives will affect where manufacturers set up their plants, and suppliers who do not develop clear carbon reduction strategies will be gradually eliminated from the industry chain in the future. The global industry chain will shift from being linked by geographic location and trade costs to being linked by environmental values and national security costs.

In the semiconductor industry, many large-scale companies are using major manufacturers from Japan, Korea, Europe, and the United States. Unimicron has been working with equipment manufacturers (e.g. copper plating machines, etching machines) and material manufacturers (e.g. 5G substrate material manufacturers and anti-solder materials suppliers) to accelerate R&D on low carbon technologies for equipment and materials as well as to gain the capacity for independent R&D in order to strengthen the market competitiveness of products in response to market risks caused by climate change. |

| Strengthen Research and Development Relationships between Industry, Academia and Research Institutes |

In response to the rise of the red supply chain and the localization of materials and equipment, the Company has adopted the model of joint development with industry, academia and research institutes to strengthen the investment in the plans of developing new technologies and new equipment; for example, joint development of new laser cleaning technologies and AI inspection technologies with academic institutions, and joint development of new self-alignment Pick & Place equipment with equipment manufacturers. In addition, we cooperate with the School of Electrical and Mechanical Engineering of a university to jointly develop new products. The school designs the test circuit, the Company produces and conducts electrical tests, and the research and development results are passed through the customer's pipeline to conduct actual verification of new product packaging and testing, creating a new product blue ocean. |

| Drive the Industry to Set New Specifications |

The platform development plan for 5G high-speed and high-frequency applications, advanced substrate platform for heterogeneous integrated IC carriers, high-end micro-LED carriers, Optoelectronic Module, and Radar Antenna Module are all brand-new projects. The industry has yet to establish a set of quality certification specifications or testing standards. We will continue to invest our development resources according to our client’s development schedule to be the first to meet our client’s standards and to become the industry benchmark for this technology platform so that the industry will make this technology platform the standard process for the industry. In 2022, we collaborated with customers to develop Radar Antenna Module and exhibited it at the TPCA show. |

R&D Cooperation Plan

|

Cooperation |

Benefits |

Cooperation with Suppliers Cooperation with Suppliers |

We maintain close cooperation with excellent material and equipment suppliers, introduce high-performance materials and cutting-edge equipment for new product development, and cooperate with domestic equipment firms. Especially, 5G higher-frequency communications and the Low Df material process of high frequencies signal loss need to cooperate with material suppliers early. |

The global supply chain market is highly competitive, and the outcome of Unimicron and our suppliers’ joint effort in development has resulted in the advanced attainment of future key technologies, helping us to maintain a leading position in the industry. At the same time, it also helps to ensure that related industries in Taiwan can continue to remain to stand and in turn obtain key positions in the midst of fierce competition and industry chains in various countries becoming more autonomous and grouped. |

Cooperation with Academia Cooperation with Academia |

To strengthen new R&D relationships with industry, academia, and research, we have been cooperating with Taiwan University, Tsinghua University, National Central University, and Yuan Ze University for a long time with NT$ 22.95 million in the Industry-Academy Cooperation program. It is hoped that this will effectively utilize the research results of the academic community, activate the domestic research capacity, and encourage cross-field basic scientific research, so as to shorten the learning curve of the Company's R&D, and at the same time cultivate future scientific and technological elites |

By combining academic theories with industrial production and development practices, the difference between theory and practice can be quickly reduced, and allow advanced academic research results to be effectively and seamlessly integrated into industrial technology. Also, an important part of industry-academia collaboration is the overall planning of the collaboration, including faculty, equipment exchange, graduate student training, and funding. By operating the research environment independently under the regulations of each academic unit, the academic community can make reasonable profits and attract more outstanding academic teams to join in, forming a virtuous cycle. |

Cooperation with the Government Cooperation with the Government |

We received tax exemptions, investment tax credits and incentives for equipment, industry-specific subsidies, and R&D investment credits from the government. Following the government's priority counseling program, we proposed a new technology development plan and gained industry-specific grants. |

Government funding accelerates the development of Unimicron technologies and strengthens product competitiveness, such as introducing panel-level ETS fine line fan-out to the development of the multi-chip heterogeneous integrated packaging technology platform, which expands package size and will be applied to 5G high-frequency and high-speed communications as well as improve electrical performance. What’s more, the government can gain a good understanding of the R&D potential and development difficulties of domestic industries through this partnership, which will serve as the basis for future technology development policies. |